Fabrication Capabilities

Rigidized Metals Corporation® offers a full assortment of fabricating equipment, including shears, press brakes, panel lamination lines, turret presses and welding stations. These enable us to engage in a vast array of products and projects. Our skilled craftsmen, with decades of experience and a sense of unmatched quality, execute everything from prototypes to complete projects, offering our customers services from concept to completion.

Our Equipment Includes:

- Shear: 48-inch Niagara – .250 thick cap. CRCS/ .125 SS-shear – Tolerances +/- .03125″

- Shear: 144-inch Niagara – .250 thick cap. CRCS/ .125 SS-shear – Tolerances +/- 0.3125″

- Bend: 120-inch Fasti 221 32/2.5 Folding Machine – .105 stainless steel full length; .125 CRCS full length segmented tooling (low-cost setup) – Tolerance +/- 1/32″

- Bend: 144-inch Cincinnati Press Brake – .125 stainless steel full length; .25 CRCS full length, segmented tooling (low cost setup) – Tolerance +/- 1/32″

- Punch: 22 ton Trumpf Turret Punch – Max punch capability: .125 stainless steel (no nibbling); .125 CRCS – Auto indexing head: 16 stations – Max sheet size: 60×144

- Punch: 35 ton Finn Power Turret Press – Max punch capability: .125 stainless steel (no nibbling);.125 CRCS – Auto indexing head: 20 stations – Max sheet size: 48×144

- Laser Cutting System: Cincinnati CL-920 Laser System – 2000 watt – Bed size: 79×158 – Speed: 8500 ipm – Z-axis hold height: 10 – Drives: Linear – Capacity: 0.25″ 304; 0.25″ CRCS; 0.25″ Aluminum; 0.125″ Copper/Brass – Tolerance +/- .001″; Repeat accuracy: .0002″

The Rigidized® Metals fabrication team offers:

- Full time technical support for engineering needs

- Fast quotes, interpreted from customer’s fully dimensioned drawings

- Multiple drafting packages allowing customers to submit .DWG and .DXF for quotation

- All jobs manufactured from shop drawings provided by Rigidized® Metals for approval

Our designers and fabricators can assist with project and product design concepts and ideas. Our team is capable of developing simple concept renderings, or, if needed, complete detailed drawing sets. This seamless and transparent design collaboration ensures timely and successful execution of projects, and can be achieved all under one roof.

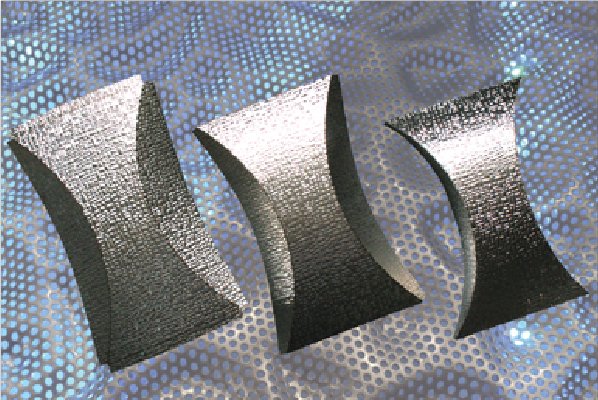

Curved Panels

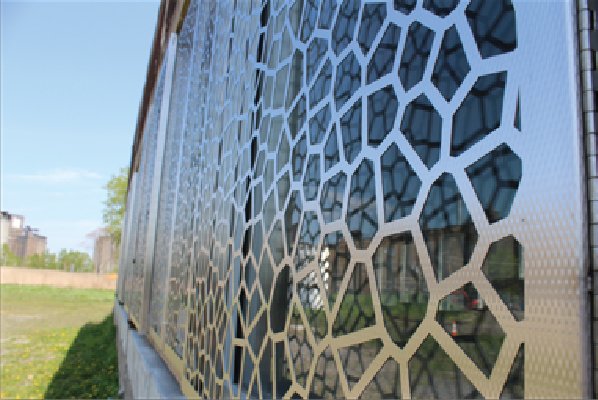

Perforated, Curved Sculptures

Custom Screens

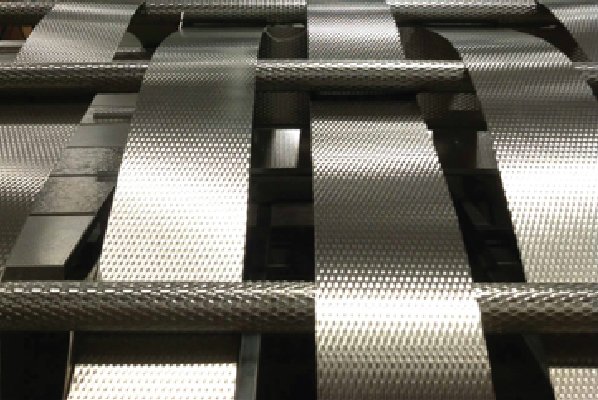

“Weaving” Capabilities

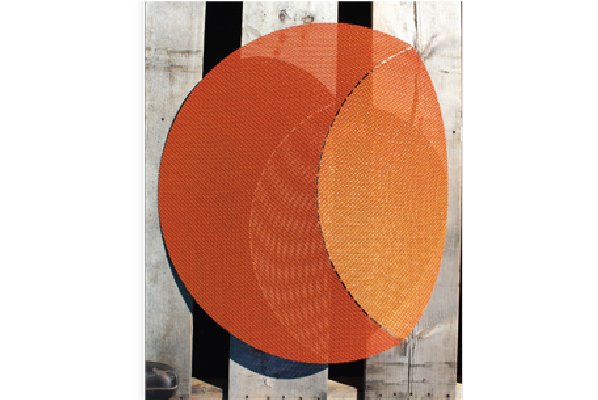

Custom Perforating and Bending

Logos and Signage