Paneling Options

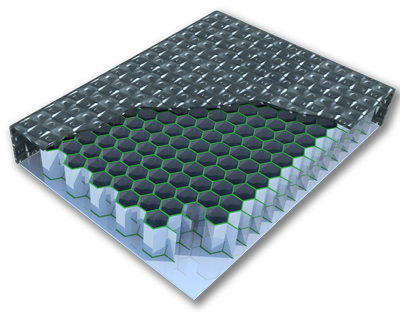

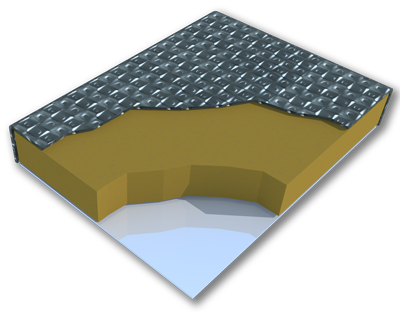

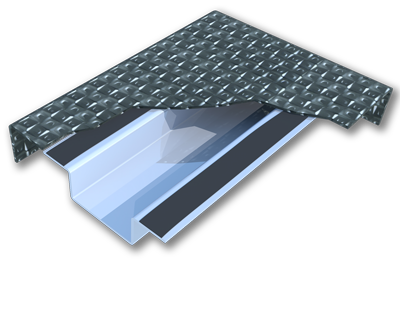

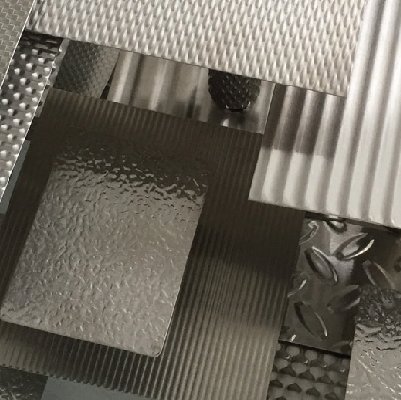

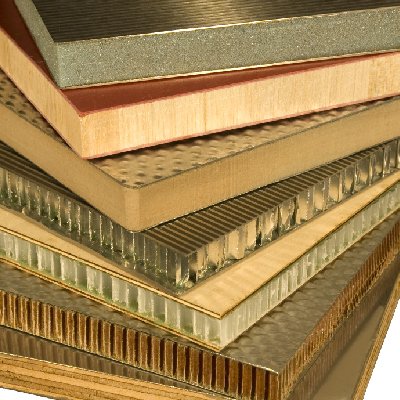

Rigidized® Metals offers an array of modesty panels for several different types of transportation applications. Panel cores enhance physical and acoustic properties of the panels. Panels can be faced in stainless steel, aluminum, copper, brass, bronze and steel in thicknesses of .016″-.090″. Mechanical finishes include mill, polished, embossed and Rigidized® Metals engineered surfaces. Powder coated and colored stainless steel are also available. Panel thickness can be from 1/4″ to 2″ with the length and width limited to the panel face material (stainless steel 60″ x 144″). We can supply a premium fire rated MDFB or an aluminum honeycomb core laminated with an FR adhesive.

Recommended Patterns

Explore the Rigidized® Metals products that are used in this application.