Anodzied InvariMatte® Aluminum

InvariMatte® stainless steel is well recognized as the gold standard of low glare stainless steel surfaces designed for architectural applications. Millions of square feet have been installed around the world with building owners enjoying beauty, energy savings and low maintenance. And now, this amazing engineered surface is available as an anodized aluminum product.

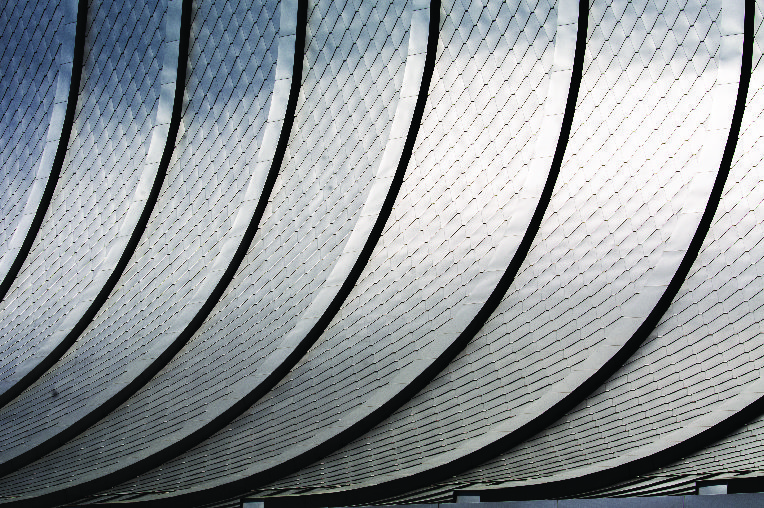

Arthur J. Altmeyer Social Security Administration Building

Kendall McCaugherty © Hall+Merrick Photographers