Panels

Rigidized® Metals offers an array of panels to suit your needs. From fire rated, laminated and ASTM-certified panels to acoustical panel systems for aesthetic noise-maintenance, our products are sure to provide a solution that you need, while maintaining your design intent.

For full systems, please see:

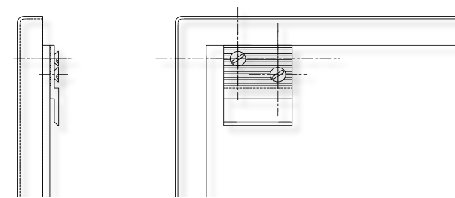

Example Corners

Beautifully finished corners are the hallmark of a superior quality panel manufacturer. Corners exemplify the attention to detail and pride in architectural panel construction. In the industry, there are typically two types of corners offered: open and welded. Rigidized® Metals’ 20 gauge panels boast the same impact resistance as panels made from 16 gauge ordinary sheet metal, which is twice as thick. Cutting the panel face material in half greatly reduces raw material cost and consumption.

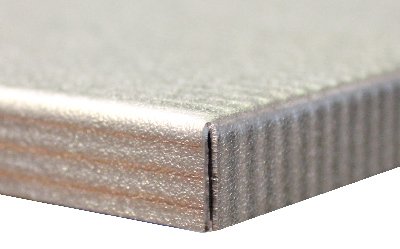

Open Corner

Welded Corner

Panel Cores

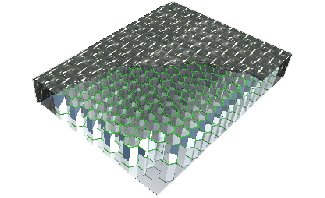

Honeycomb Core

With aluminum honeycomb cores, the honeycomb is laminated with FR adhesive to provide an extremely strong, yet lightweight, panel. Core thicknesses are ¼” to 1 ¼”. Inquire for thicknesses beyond 1 ¼”.

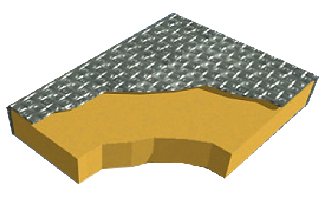

MDF Core

Solid cores include premium fire rated MDFB laminated with an FR adhesive. Plywood and standard medium density fiberboard are also available. Panel thicknesses are from 1/2″ to 2″.

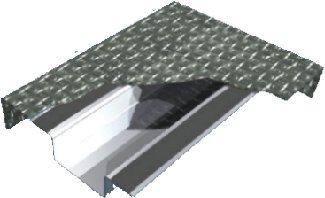

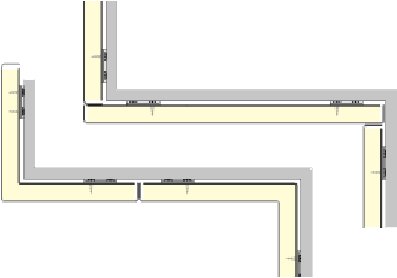

Bonded Hat Channel

Hat channels are metal elements that stiffen panels and provide mounting points for the attachment of Z-Clips. A feature of hat channels is the ability to create deeper panels (up to 2″) without adding significant weight to the assembly.

Z-Clip Attachment System

Made from extruded aluminum, Z-Clips are the most popular choice of professional installers because they install in minutes. Z-Clips are available in a wide variety of widths and lengths. Simply attach the wall Z-Rail to a wall surface and drop in the factory attached panel slip and panel assembly.

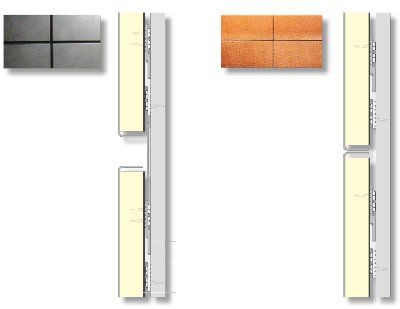

Reveal and Butt Joints

Reveal joints allow for the addition of complementary or contrasting elements between the panels. Wood veneers can be used to create a wide variety of effects. The image of the panels with reveal (the left-most image to the right) are 304 stainless steel with non-directional polish. Butt joining the panels utilizes the same attachment system without the need for a second material between the panels. The image of the panels butted (the right-most image to the right, and the top-most image, below) are copper with pattern 1CS.

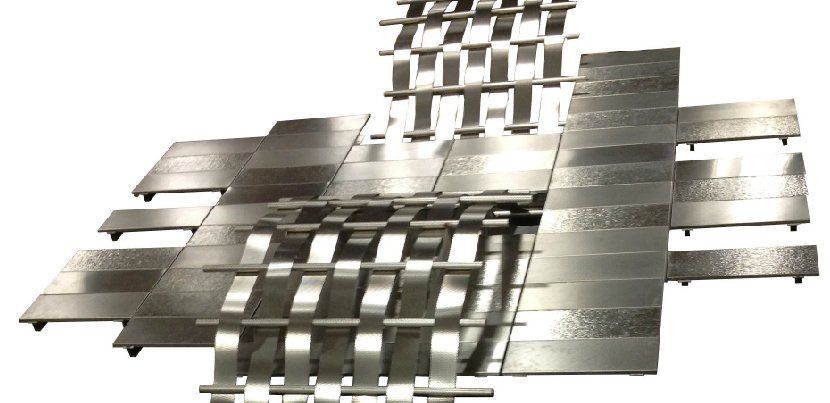

Unbacked Panels

Rigidized® Metals has created a starting design, allowing a “greener” un-laminated panel to be mounted directly to metal “hat channels” or wood furring. From there, you can move your design ideas quickly to custom solutions unique to your vision.

A large selection of textures allows the designer the ability to mix and match surfaces to create unique effects, and, because the textures are created in the metal and are not a coating system, it is easy to provide a greener installation.

Our flexible CAD manufacturing methods allow the panels to be cut with custom sizes, features, and mounting configurations. Panel sizes and details can vary within the production run to integrate with the “mass customization” concepts of today’s projects.

Explore related applications by clicking on these links for more information.