InvariMatte® Engineered Metal Surfaces for Structural Roofing

A roof is typically the single highest maintenance item on a building. Making the right material choice can really pay dividends for the building owner in terms of reduced maintenance and operating costs.

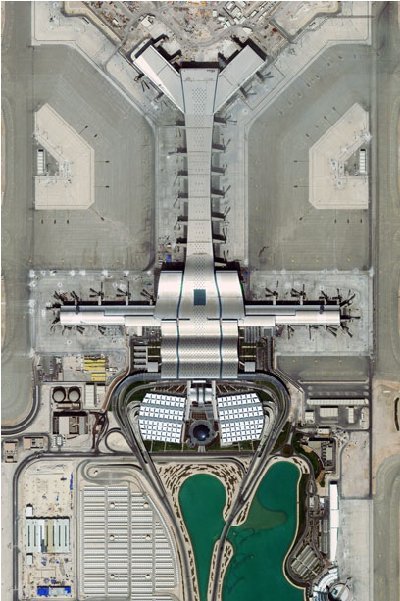

Hamad Airport in Doha, Qatar has a 4 Million square foot roof made of duplex alloy InvariMatte® stainless steel. Aside from looking great, the high performance alloy makes all the difference in this severe marine environment.

A proper roofing material will:

- Last as long as the building is in service

- Clean itself naturally

- Reflect solar radiation efficiently in order to:

- Save energy

- Reduce the heat island effect

- Combat climate change

- Prevent glare

- Reduce damage losses

- Maintain property value

InvariMatte® stainless steel delivers all of the above extraordinarily well without a coating of any kind. The new anodized aluminum version of InvariMatte® outperforms typical aluminum surfaces with a lower acquisition cost compared to its stainless steel counterpart.

Large scale projects require structural roofing panels strong enough to deal with the added wind uplift that large surface areas create. A great deal of engineering goes into creating a proper roof to meet the required surface conditions of a given project. While Rigidized® Metals does not produce structural roofing panels, we are a significant supplier to the roofing industry. We urge designers to spend some time thinking about the metal material and its surface because that part of the design matters greatly.

A metal roof made with the right alloy system can last indefinitely and the right surface design can promote cleanliness and save energy. It is therefore very important to consider what metal your roof gets built with.

A Rigidized® Metals representative can help you determine which material choice is ideal for your application and site location.

The Jamaica Air-Train Terminal at JFK Airport in New York has a structural batten seam system made with InvariMatte® stainless steel. Note there is more reflection showing from indirect sunlight on the transit cars that can be seen in direct sunlight on the roof. InvariMatte® has lower gloss than many paint finishes, but still has a beautiful metallic appearance.

Projects of Any Size

Rigidized® Metals’ engineered surfaces have been used on large scale projects including the Hamad International Airport, the largest stainless steel roof in the world, and major exterior facade projects like Via 57 West in New York. However, they are also available for projects of any size, including those that do not require structural roof panels. The same high performance roofing material used on major airport roofs can be shipped in the form of installable roof, exterior wall and gutter systems for light commercial and residential projects.

The Willow School in NJ has an InvariMatte® stainless steel roof. A true structural roof was not needed here, but this high performance material looks great on projects on any size.

The parabolic shape of the façade of Via 57 West in New York posed a high risk of glare. InvariMatte® was a safe, yet beautiful solution.

InvariMatte® Stainless Steel

Painted metal roofs are commonplace. They do a good job of protecting the building for a period of time in the color of your choice. In the long term, however, paint systems lose their solar reflectance and the metals they protect can corrode from the back side or in areas that are damaged, as in the case of a hail storm.

Instead, InvariMatte® stainless steel is an engineered surface texture that does not lose its solar reflectance over time, because its chromium oxide layer, a natural radiant barrier, is kept clean because of InvariMatte®’s hydrophobic surface.

Learn more about InvariMatte® stainless steel for roofs, here.

InvariMatte®

This satellite image of Hamad Airport provides a sense of the project’s massive scale, but also of the impressive uniformity of the InvariMatte® bare metal surface. The foreman who oversaw the forming of the roof panels reported that the InvariMatte® surface was more uniform than any painted metal roof project he had ever run.

Hydrophobic surfaces are ideal for roofing. They are continuously cleaned naturally so long as rainwater can rinse the metal surfaces.

Stainless steel is a very efficient reflector of solar energy, which offsets global warming and the heat island effect, and also substantially reduces insulation requirements. Unlike other bare metals that patina or paints that oxidize, hydrophobic stainless steel surfaces retain all of their original solar reflectance and energy efficiency for as long as they remain installed. While the accumulation of dirt will have a detrimental effect on solar reflectance, InvariMatte®’s dirt-resistant surface has shown zero degradation in 10 years. There are many other environmental benefits that make this the “metal made better” from a sustainability standpoint.

The impressive uniformity of InvariMatte® stainless steel can be seen on the roof of Sacramento Airport terminal in California.

Structural standing seam roof panels made of duplex alloy InvariMatte® stainless steel on the Hamad International Airport in Qatar.

A permanent roof is possible. Even in the toughest environments, it will look good while it saves the building owner maintenance and operating costs.

While the color of your choice is not possible here, the color of the environment is often a more elegant choice, letting nature and the surrounding built environment become part of the design.

InvariMatte® stainless steel batten seam panels on the Pittsburgh Convention Center in Pennsylvania.

The InvariMatte® stainless steel surface on the globe at the Raleigh Science Center in North Carolina changes its appearance based on both natural and artificial lighting conditions. InvariMatte® is the color of its environment.

InvariMatte® Aluminum

The highly engineered surface texture of InvariMatte® is now available in anodized aluminum, which can make a great deal of sense for many roof projects.

- Sophisticated appearance

- Lower cost and lighter weight

- Coil anodizing promotes uniformity

- Colors are available upon request!

Photo by: Kendall McCaugherty © Hall+Merrick Photographers

The Arthur J. Altmeyer Building in Bethesda, MD has vertical panels made with InvariMatte® Aluminum. The crisp, high end appearance of these panels would look just as good on a roof.

Other Options

We produce the InvariMatte® engineered surface in other metal alloy systems like copper and titanium. A Rigidized® Metals representative can work with you to find the best solution for your project!

Hamad Airport is built on soil reclaimed from the Gulf. The corrosion performance of the metal used for the roof had to be up to the challenge of this environment. The result was the first ever duplex alloy stainless steel (the same grade used on offshore drilling rigs) roof. Rigidized® Metals can help you solve your design challenges, too.

Explore related Rigidized® Metals products and markets.