Grip Comparison Guide

The table below compares the friction and grip-ability of selected samples. Specimens were tested in dry, wet and oiled conditions. Independently tested material and devices are not to ASTM specification. Testing was based on ASTM G115-98 (testing coefficient of friction), ASTM A947M-95 (specs for textured steel), and ASTM A554 (standards for manufactured tubing). The data is provided as a selection guide and is not intended to substitute for certified testing.

| Sample | Kinetic Friction Forces Dry | Kinetic Friction Forces Wet | Kinetic Friction Forces Oil | Gripability (Lbs/Inch) Dry | Gripability (Lbs/Inch) Wet | Gripability (Lbs/Inch) Oil | Coefficient of Friction Dry | Coefficient of Friction Wet | Coefficient of Friction Oil |

|---|---|---|---|---|---|---|---|---|---|

| 1.50″ D 304 Stainless Steel Flat no pattern | 6.917 | 9.00 | 3.22 | 1.47 | 1.91 | 0.68 | 1.02 | 1.33 | 0.48 |

| 1.50″ D RGM 304 Stainless Steel (Black powder coat) | 12.583 | 13.17 | 1.23 | 2.67 | 2.79 | 0.26 | 1.86 | 1.94 | 0.18 |

| 1.50″ D RGM 304 Stainless Steel | 11.200 | 9.17 | 1.05 | 2.38 | 1.95 | 0.22 | 1.65 | 1.35 | 0.16 |

| 1.25″ D RGM 304 Stainless Steel | 19.00 | 15.44 | 2.45 | 4.84 | 3.93 | 0.62 | 2.81 | 2.28 | 0.36 |

| 1.25″ D 3SL 304 Stainless Steel | 7.38 | 4.81 | 0.35 | 1.88 | 1.22 | 0.09 | 1.09 | 0.71 | 0.05 |

| 1.25″ D RGM Inverted CRCS | 5.00 | 8.56 | 2.15 | 1.27 | 2.18 | 0.55 | 0.74 | 1.26 | 0.32 |

| 1.25″ D Flat (Ornament) 304 Stainless Steel | 4.56 | 7.45 | 1.95 | 1.16 | 1.90 | 0.50 | 0.67 | 1.10 | 0.29 |

| 1.25″ D Flat (TSA) 304 Stainless Steel | 3.08 | 6.35 | 1.45 | 0.78 | 1.62 | 0.37 | 0.45 | 0.94 | 0.21 |

What the Data Means When Selecting Rigi-Grip®

Textured 1.5″ D .048″ or .060″ thick walled stainless steel tubing:

- Developed 1½x more kinetic friction than plain stainless steel tubing with no pattern (TSA).

- Has 1½x more grip-ability than plain stainless steel tubing with no pattern (TSA).

- Has increased the coefficient of friction by 1½x more than plain stainless steel tubing with no pattern (TSA).

Textured 1.5″ D .048″ or .060″ thick walled stainless steel tubing (Powder coated):

- Developed 1x more kinetic friction than plain stainless steel tubing with no pattern (TSA).

- Has 1x more grip-ability than plain stainless steel tubing with no pattern (TSA).

- Has increased the coefficient of friction by 1x more than plain stainless steel tubing with no pattern (TSA).

Textured 1.25″ D .048″ or .060″ thick walled stainless steel tubing:

- Developed 6x more kinetic friction than plain stainless steel tubing with no pattern (TSA).

- Has 6x more grip-ability than plain stainless steel tubing with no pattern (TSA).

- Has increased the coefficient of friction by 6x more than plain stainless steel tubing with no pattern (TSA).

Textured 1.25″ D .048″ or .060″ thick walled stainless steel tubing (Powder coated):

- Has developed 4x more kinetic friction than plain stainless steel tubing with no pattern (TSA).

- Has 4x more grip-ability than plain stainless steel tubing with no pattern (TSA).

- Has increased the coefficient of friction by 4x more than plain stainless steel tubing with no pattern (TSA).

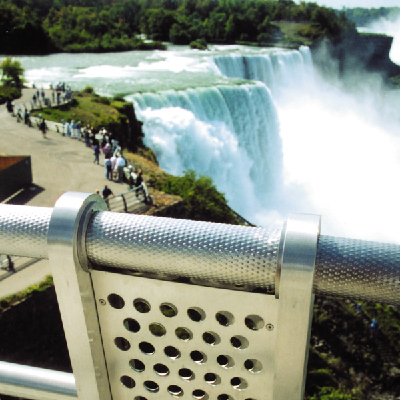

Explore related applications by clicking on these links for more information.