Our Story

When Rigidized Metals Corporation®, originally Rigid-tex® Corporation, was founded in 1940, its main thrust was to provide deep textured metal for industrial applications. Today, over 80 years later, with its third generation of family-owned leadership, Rigidized® Metals continues to lead the world in the development and production of engineered surfaces, now used in architectural, industrial, and transportation applications.

Rigidized® Metals proudly produces engineered surfaces in Buffalo, NY, USA. From serving the war effort in the 1940s to providing solutions and offerings for transportation, aerospace, architecture and design today, Rigidized® Metals’ products can be found in a wide array of applications, including the futuristic IBM Building (now the United Steel Workers Building) in Pittsburgh, the iconic Unisphere in New York City, Cave of the Winds in Niagara Falls, NY and hundreds of other installations and countless applications, providing a strong, uniquely beautiful, and highly durable solution.

We believe domestically sourced products and materials provide better quality, reliability, and availability. That’s why we at Rigidized® Metals proudly manufacture all of our products in Buffalo, New York, USA and make every effort to source all materials that comprise our products domestically. We believe in providing opportunity for local and domestic manufacturers and their employees and communities. On the very rare occasion that we need to procure materials from international sources, we do so with complete transparency and only work with socially and environmentally responsible international vendors.

Family

Launched with the singular notion that deep texturing metals would improve both performance and appearance, three generations of the Smith family have guided Rigidized® Metals through many changes and challenges, always with great concern and respect for its customers, employees, and the community. Led by Richard “Stainless” Smith, the visionary founder, Richard “Sky” Smith II, the tireless marketer, and Richard “Rick” Smith III, the energetic innovator and collaborator, Rigidized® Metals remains a welcoming place for new and interesting ideas, innovative thinking, and exciting product applications.

Richard “Stainless” Smith

Richard “Sky” Smith

Richard “Rick” Smith

History

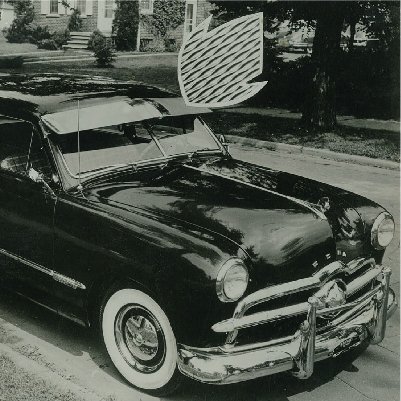

For over 80 years, Rigidized® Metals has been manufacturing deep textured metals for the industrial, architectural, elevator and transportation industries, to name just a few. The same benefits of using our textured metal on applications like kitchen counter tops and airport luggage racks have not changed. Our patterns have stood the test of time, and several of our originals are still in use today.

Throughout the company’s evolution, we were fortunate enough to have captured our products on applications in these industries from the beginning. Check out our collection of historic images by application or industry, below:

Social Responsibility

We are an Equal Opportunity Employer and do not discriminate against any employee or applicant for employment because of race, color, sex, age, national origin, religion, sexual orientation, gender identity and/or expression, status as a veteran, and basis of disability or any other federal, state or local protected class.

There is no place for racism in this world. We are a family. We hold each other up, and we hold each other accountable. We believe in justice and equality. We give respect and encouragement to everyone we encounter. When you walk through the doors of Rigidized® Metals, or meet a Rigidizer on the street, you will be celebrated as one of us, with equality and respect. As family.