Material Handling and Food Processing

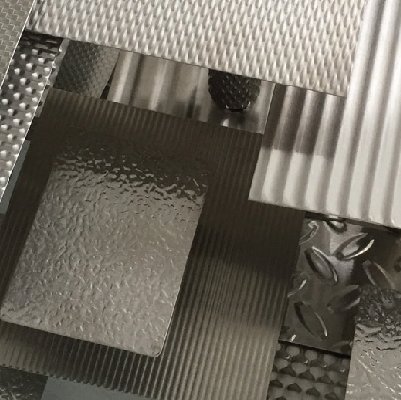

Reduce Jam-Ups with Rigid-tex®

Rigid-tex® textured metals minimize surface contact area compared with flat metals. This process greatly reduces friction, static cling, and helps end machine jam-ups and downtime. Raw or packaged materials move faster and easier through conveyors, packaging machinery, food processing equipment, and any other material handling applications.

Available in stainless steel and other metals with a choice of embossed metal patterns and finishes to meet your needs. Contact a representative to learn more.

Download our Material Handling brochure, here.

Friction Comparison of Rigidized® Metals’ Textured Metal

to Flat Steel for Chute Applications

| Flat Sheet | Flat Sheet | Rigidized® Metals Sheet (6WL®) | Rigidized® Metals Sheet (6WL®) | Improvement | |

|---|---|---|---|---|---|

| Incline Angle | Coefficient of Friction | Incline Angle | Coefficient of Friction | ||

| Static Coefficient of Friction – Dry | 19.8° | 0.36 | 17.5° | 0.32 | 12% |

| Static Coefficient of Friction – Wet | 34.0° | 0.67 | 27.0° | 0.51 | 24% |

| Dynamic Coefficient of Friction – Dry | 14.0° | 0.25 | 12.0° | 0.21 | 15% |

The coefficient of friction is a measure of the relative “stickiness” of two objects that come in contact. In this experiment, the objects were a loaded cardboard box and a sheet of chute material. For the coefficient of friction, lower numbers are better. Results will be similar for all patterns of Rigidized® Metals. The dynamic coefficient of friction is determined as the maximum angle upon which a loaded, moving cardboard box is at a condition of impending stop.

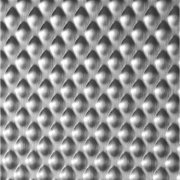

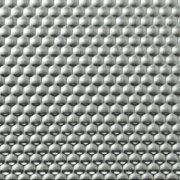

Recommended Patterns

Explore the Rigidized® Metals products that are used in this application.