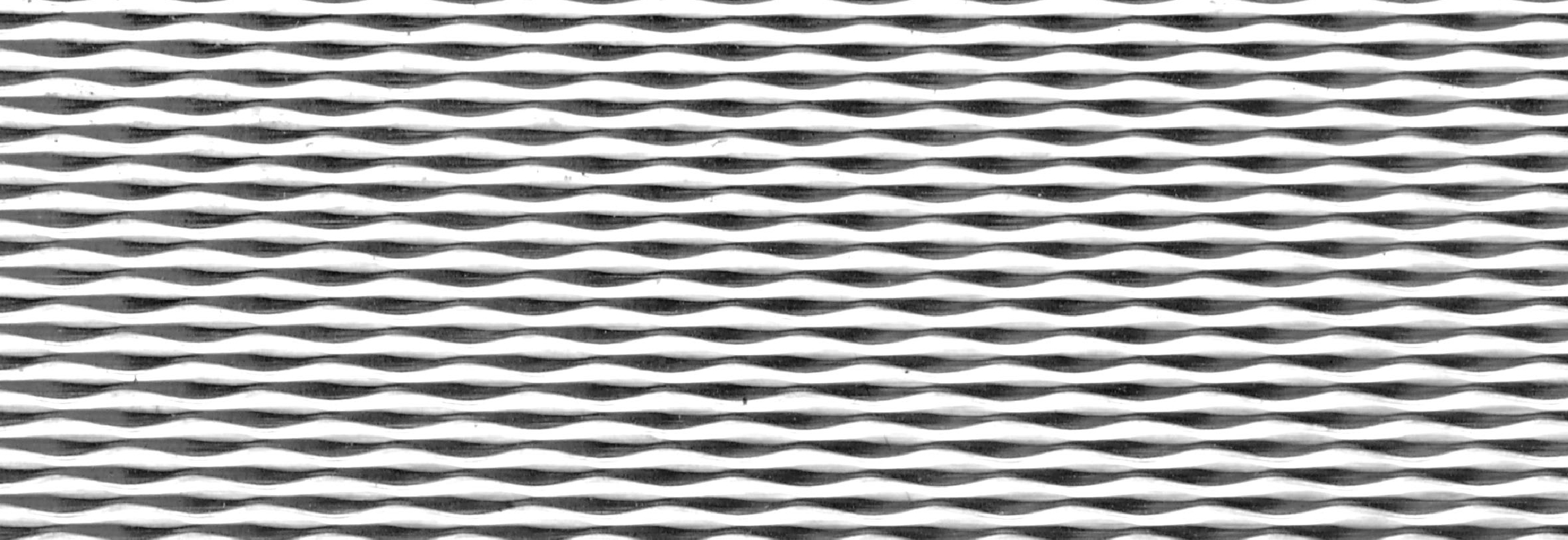

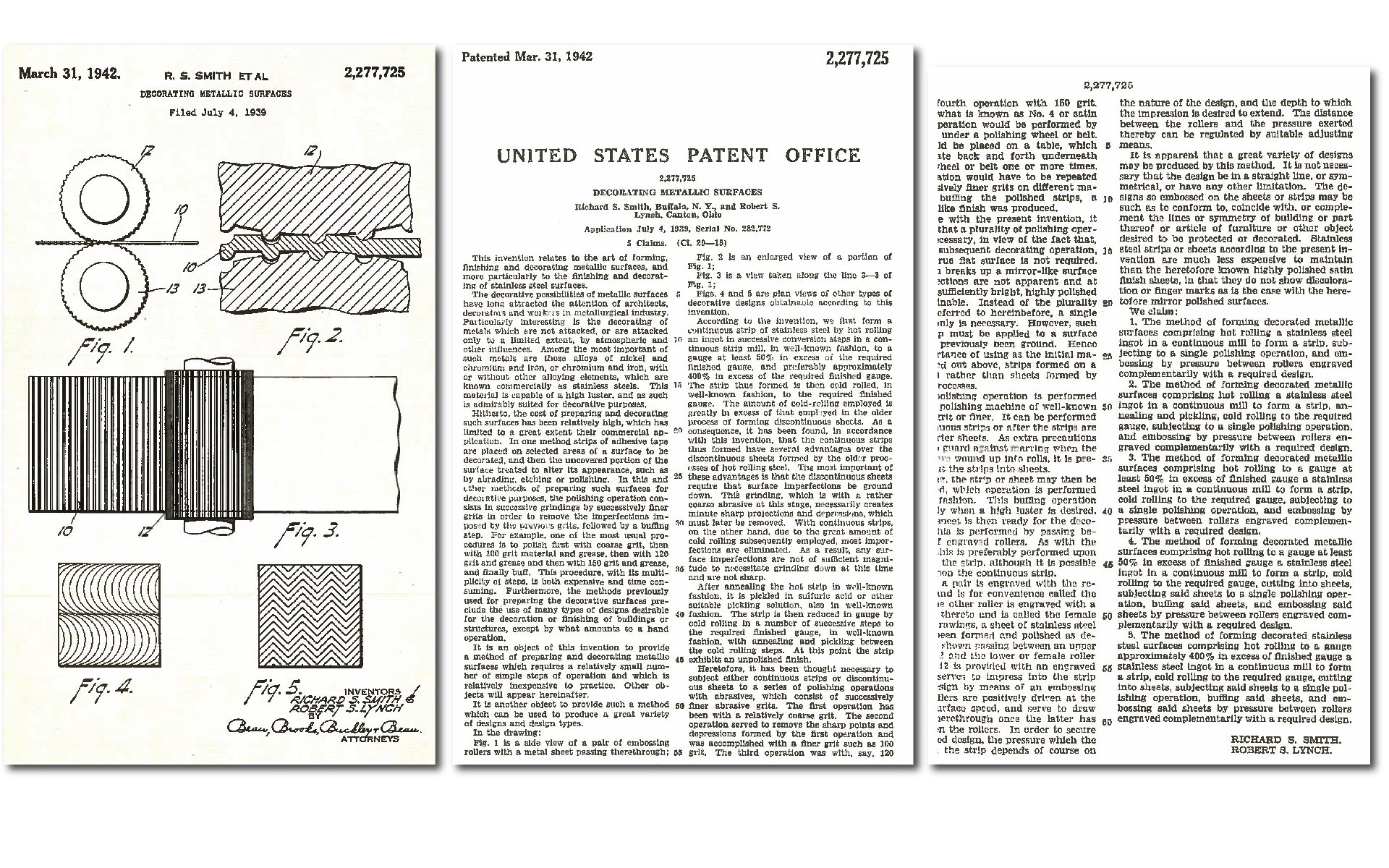

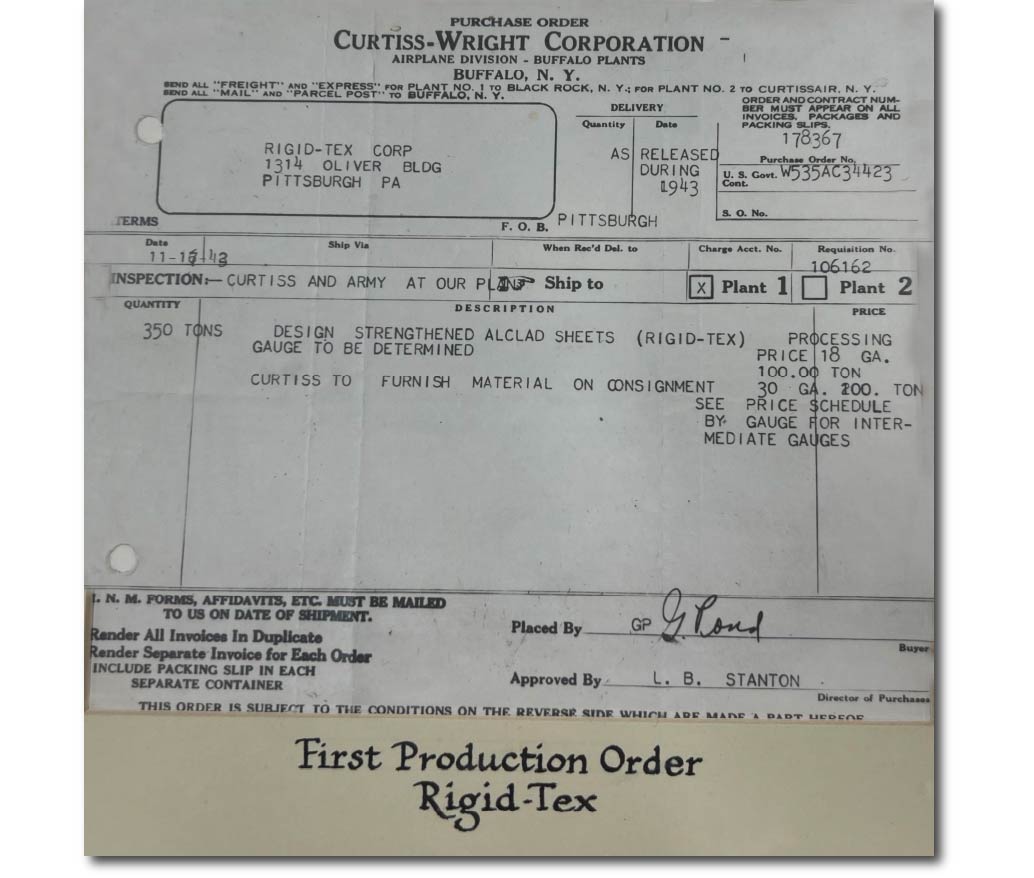

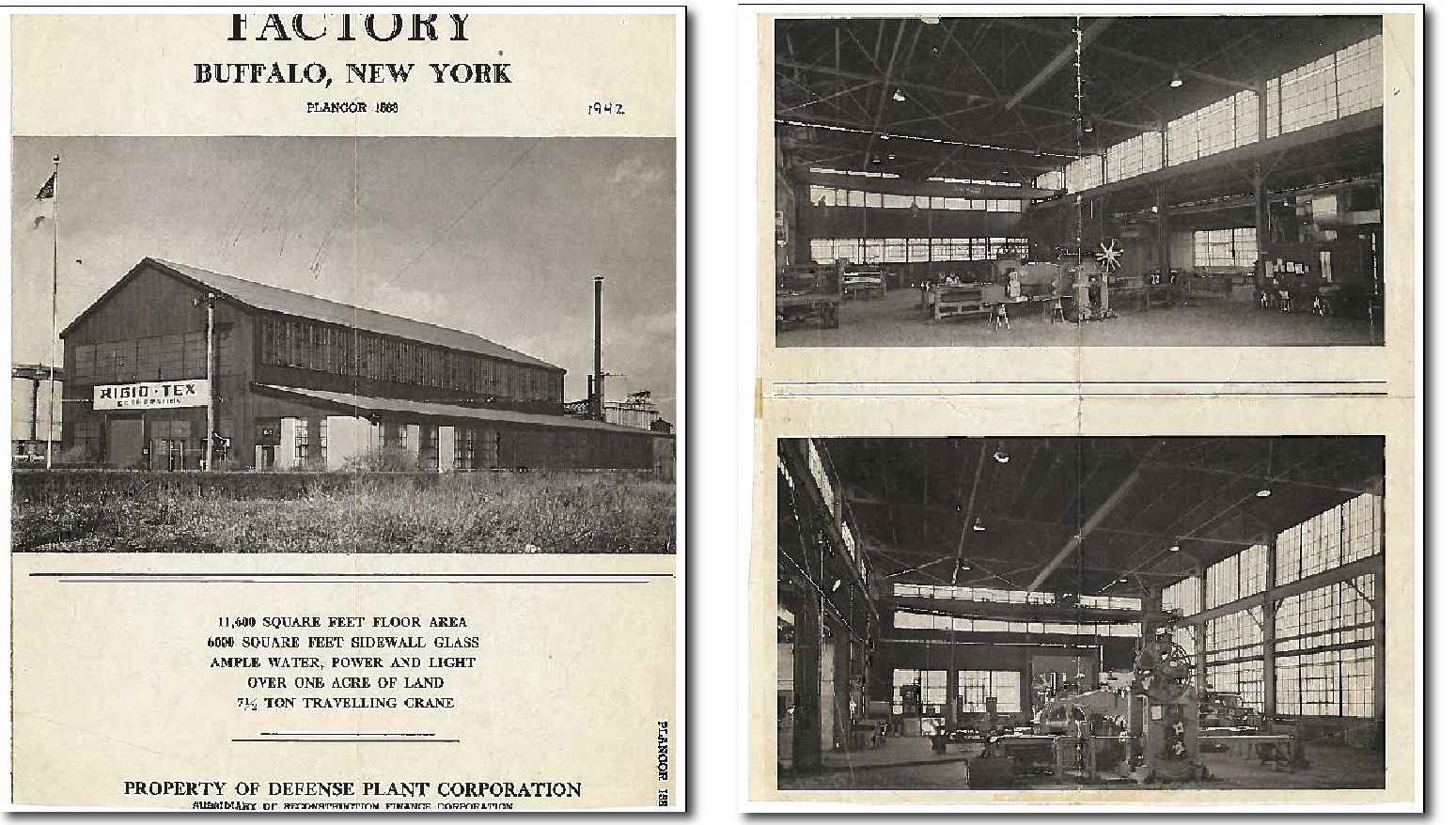

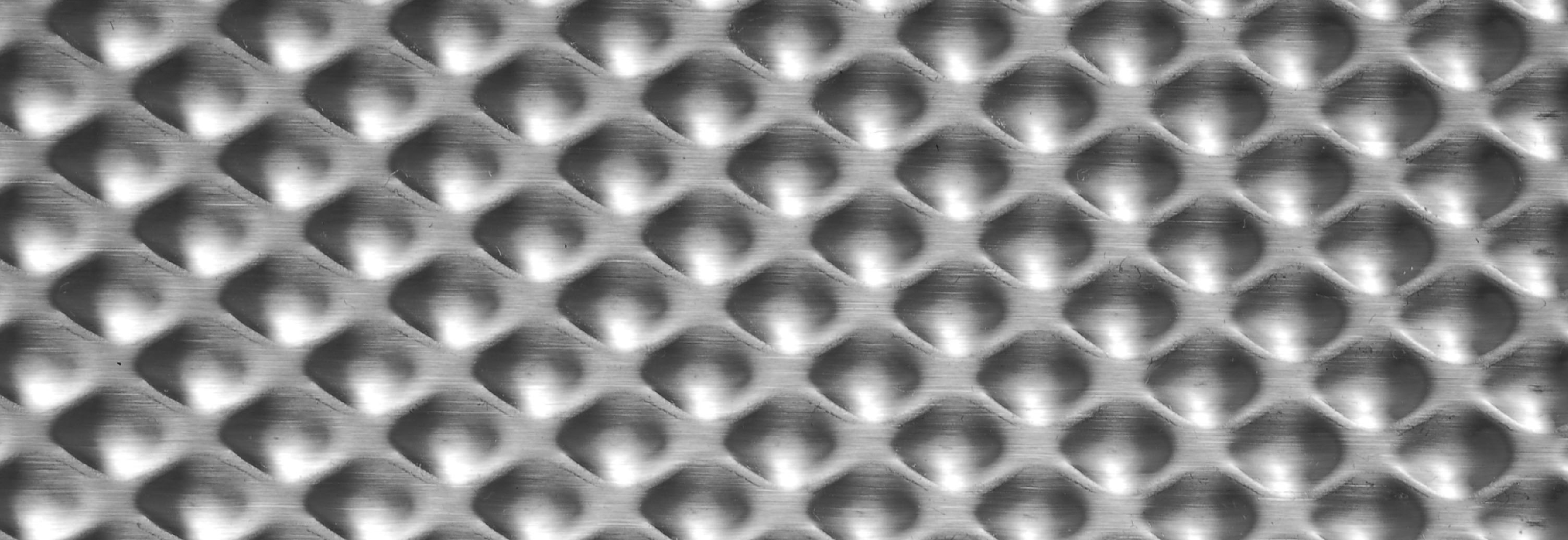

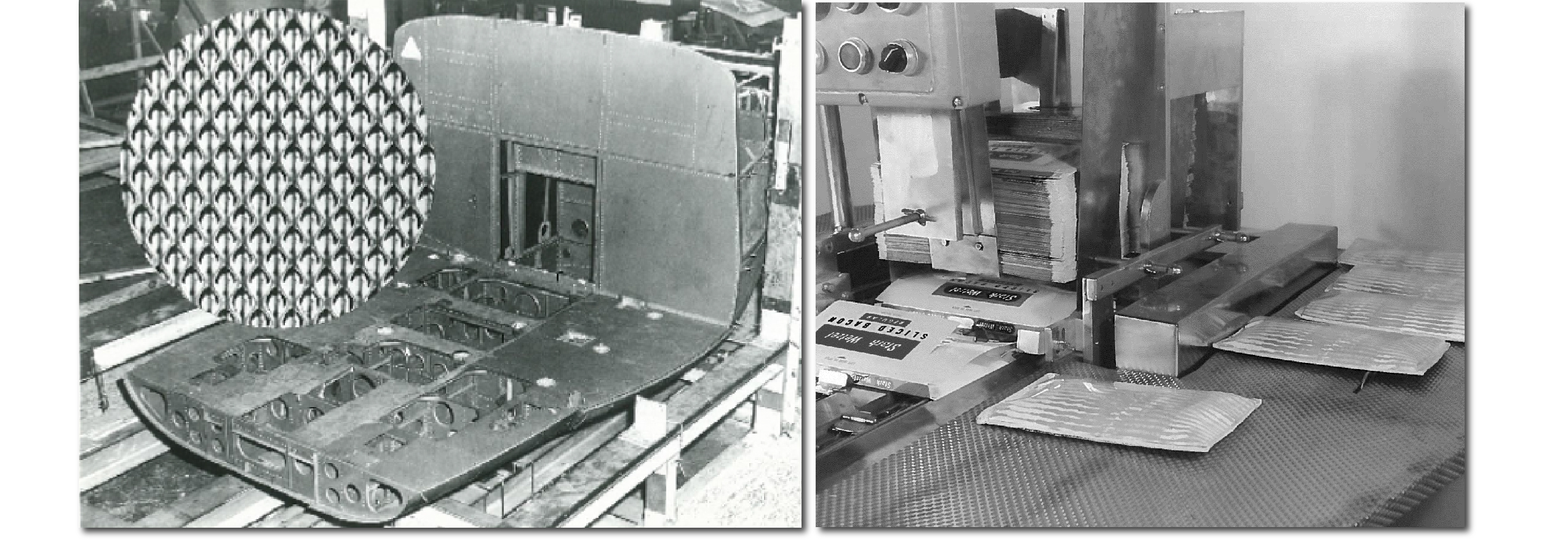

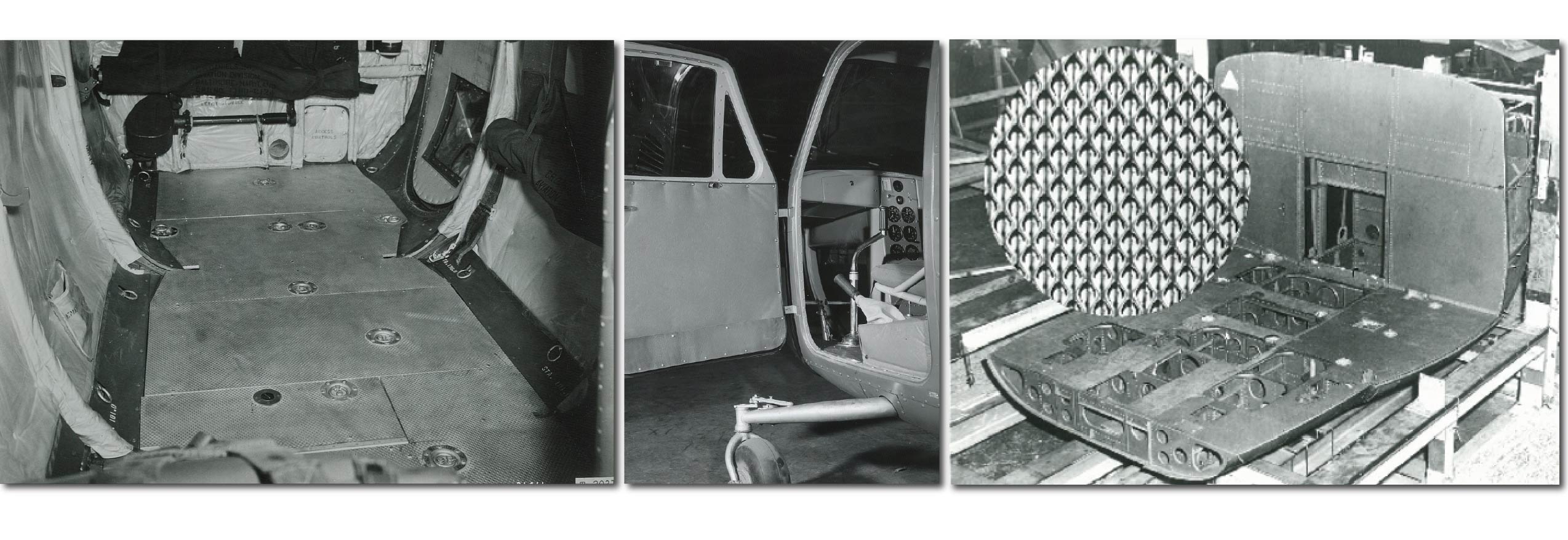

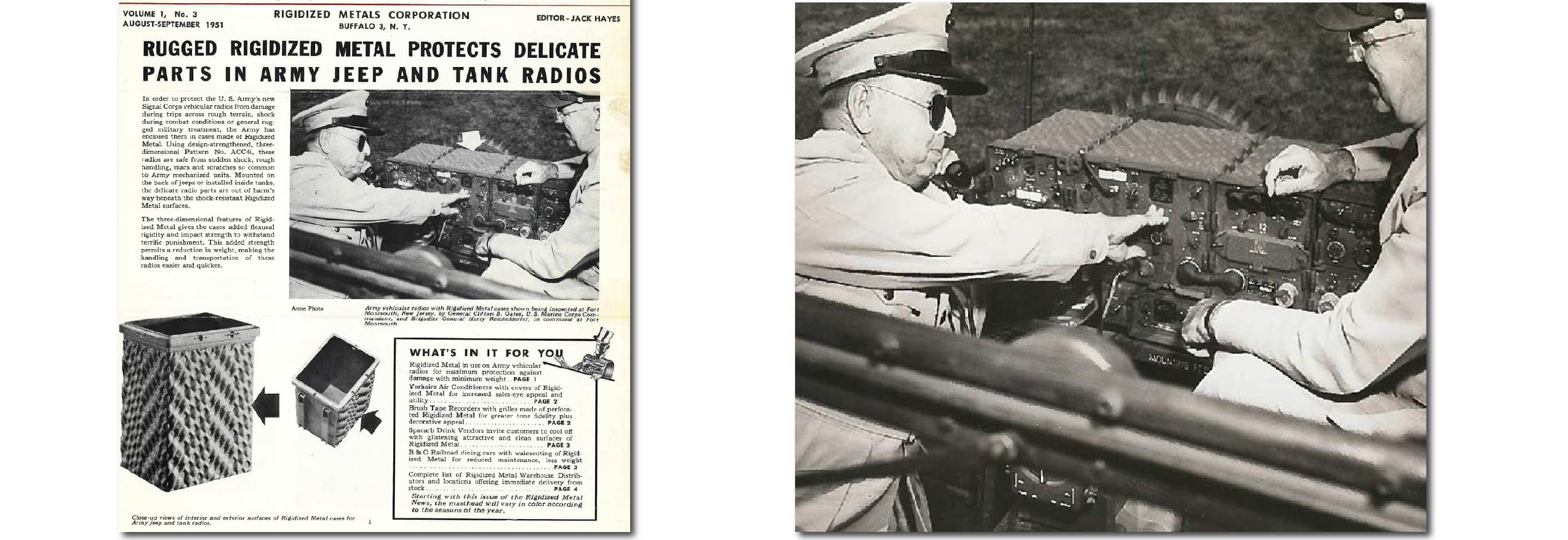

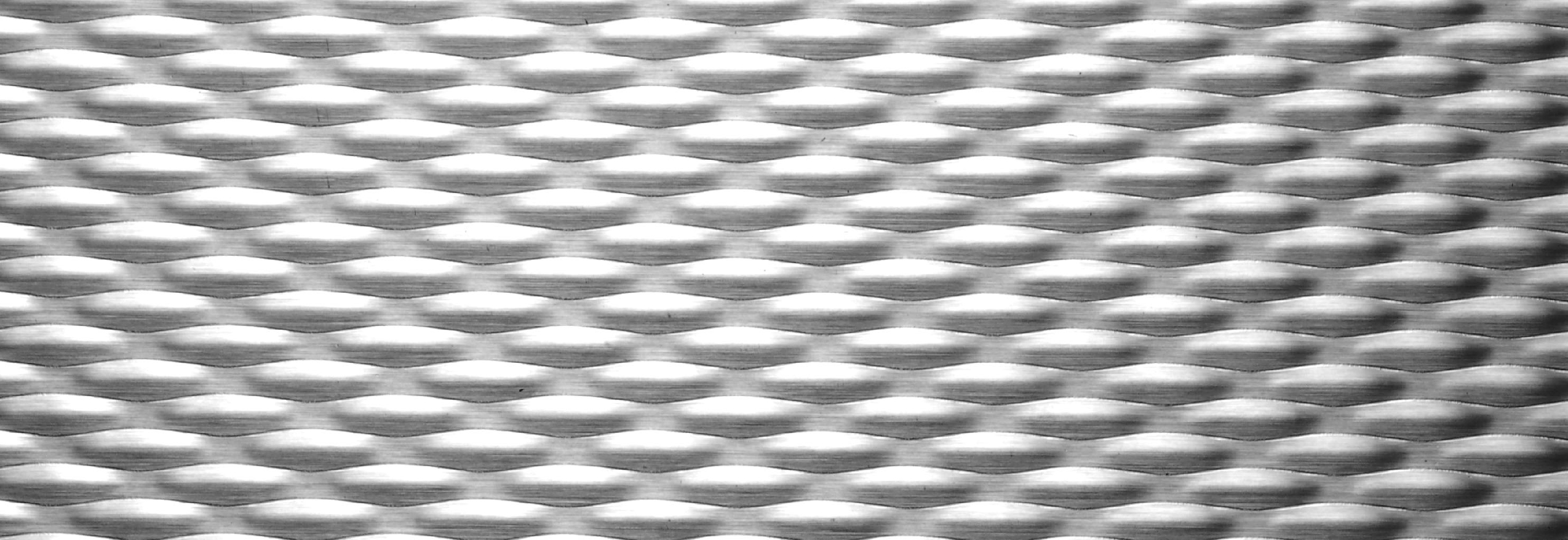

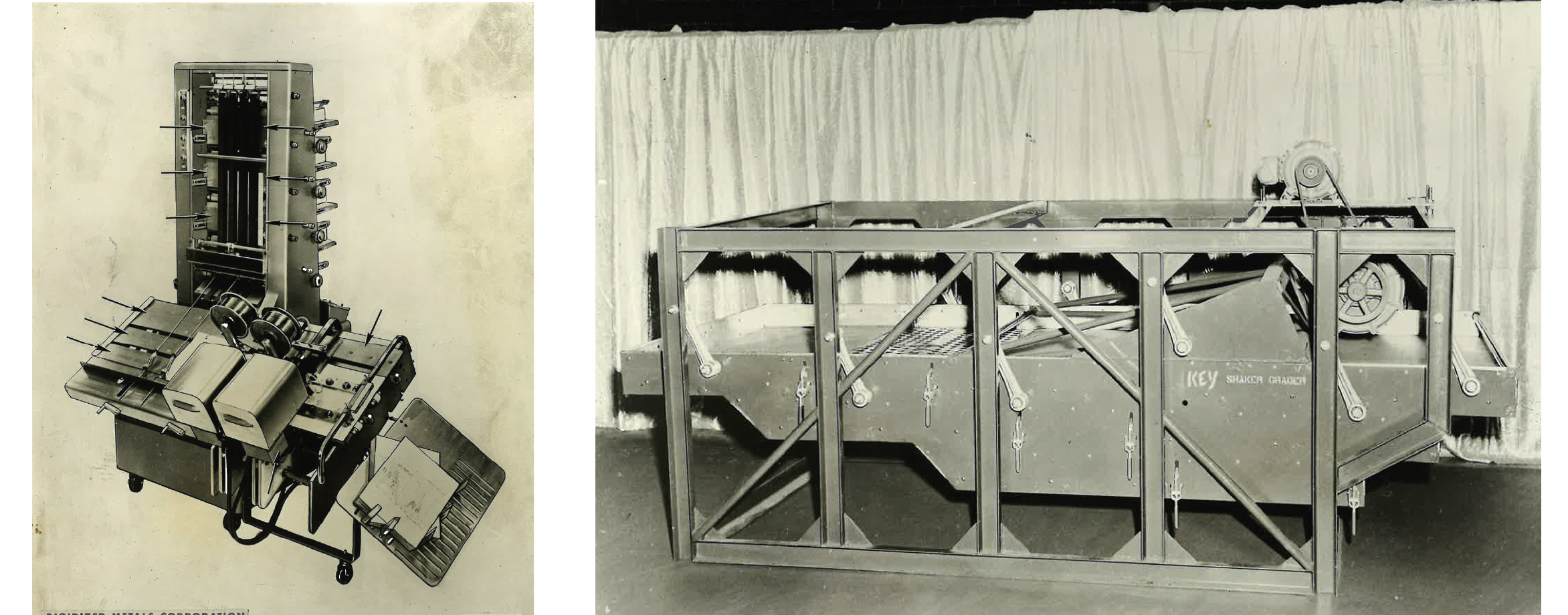

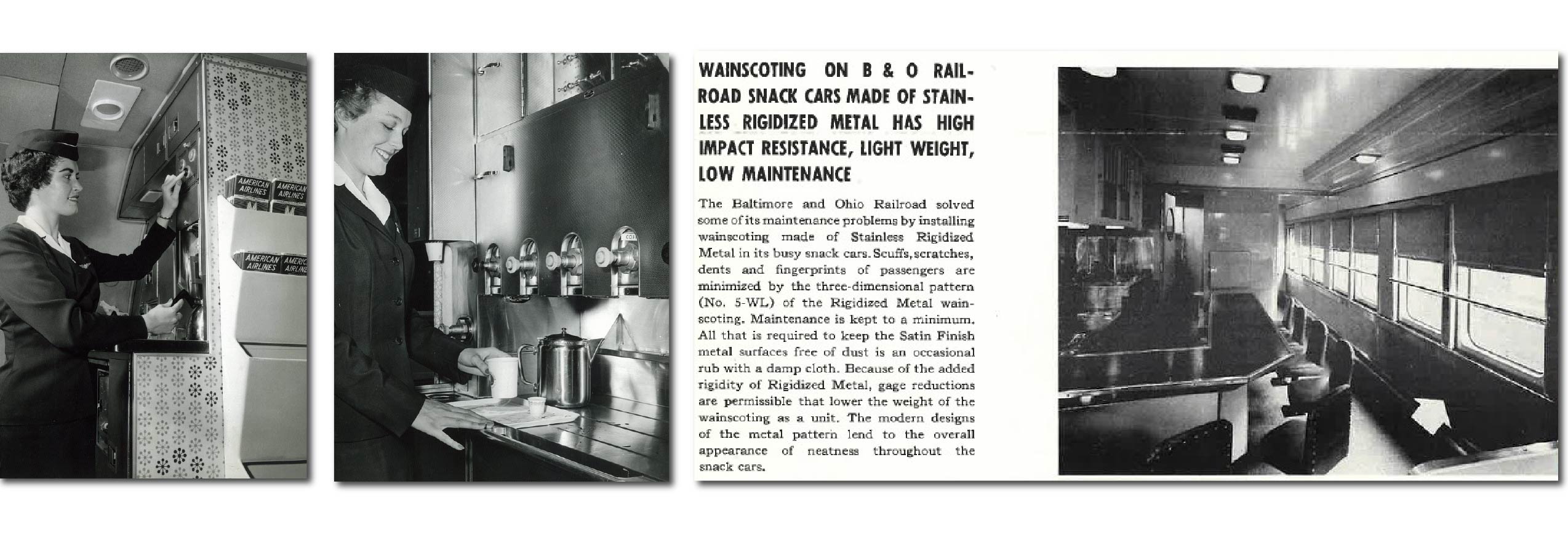

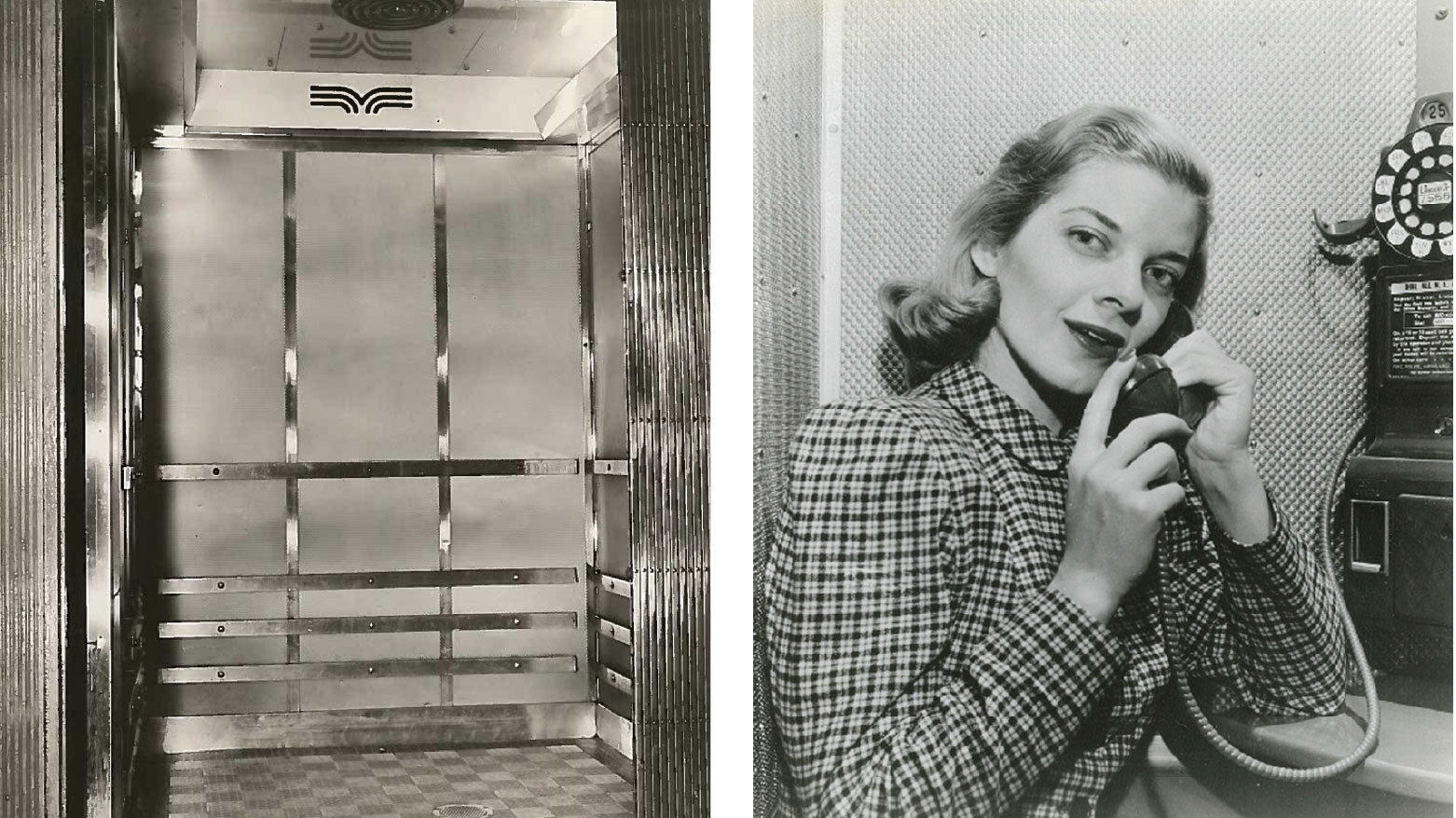

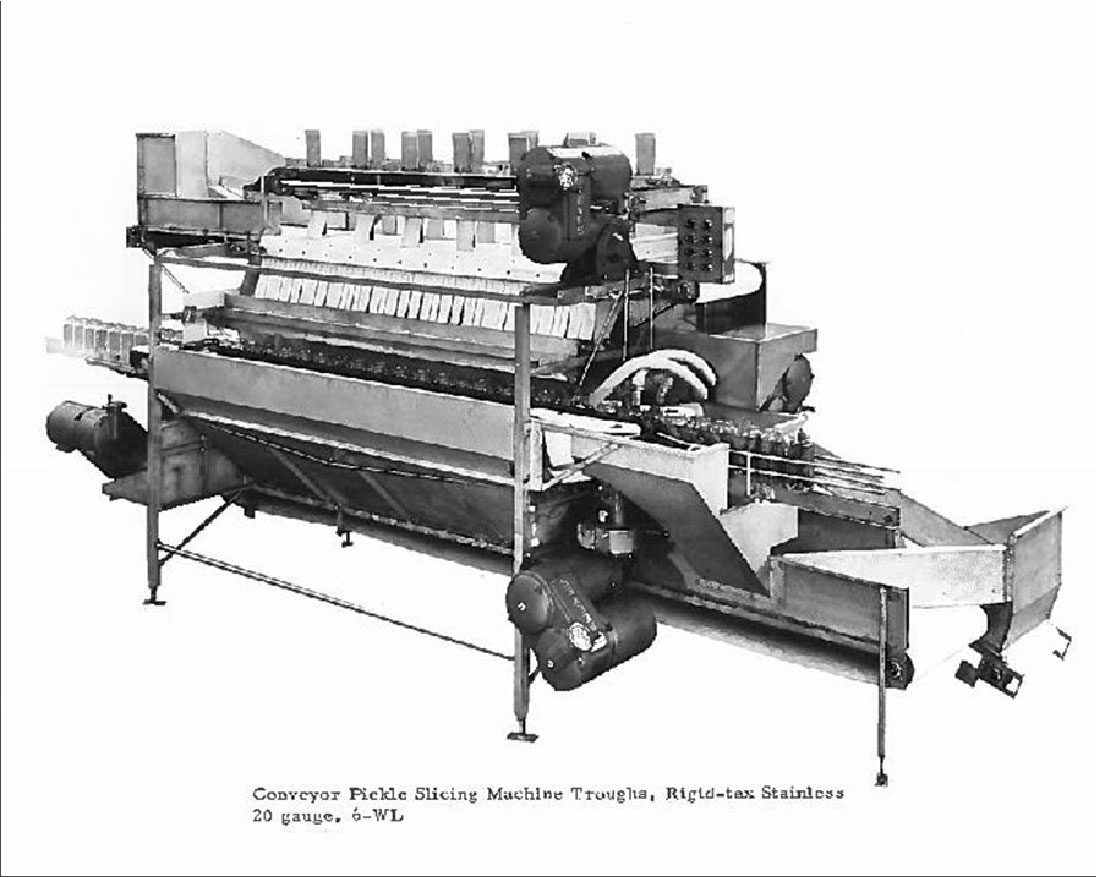

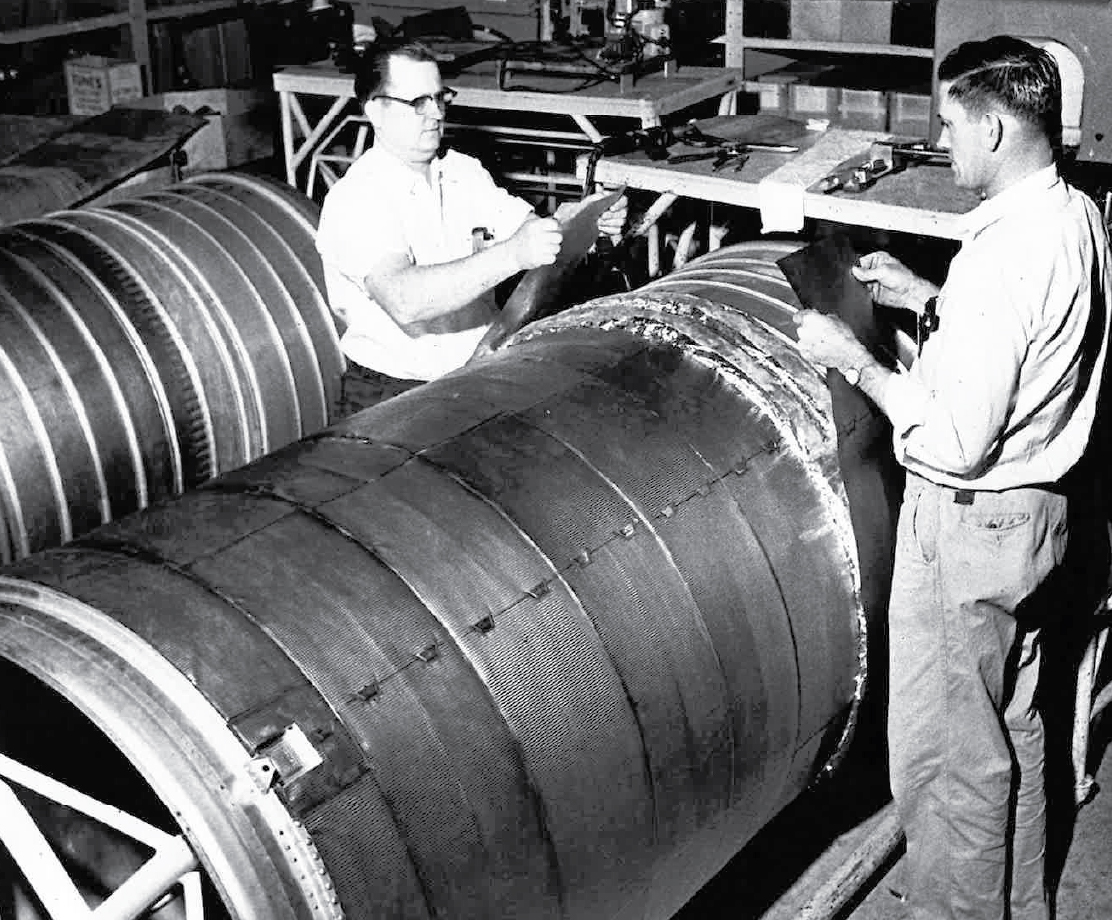

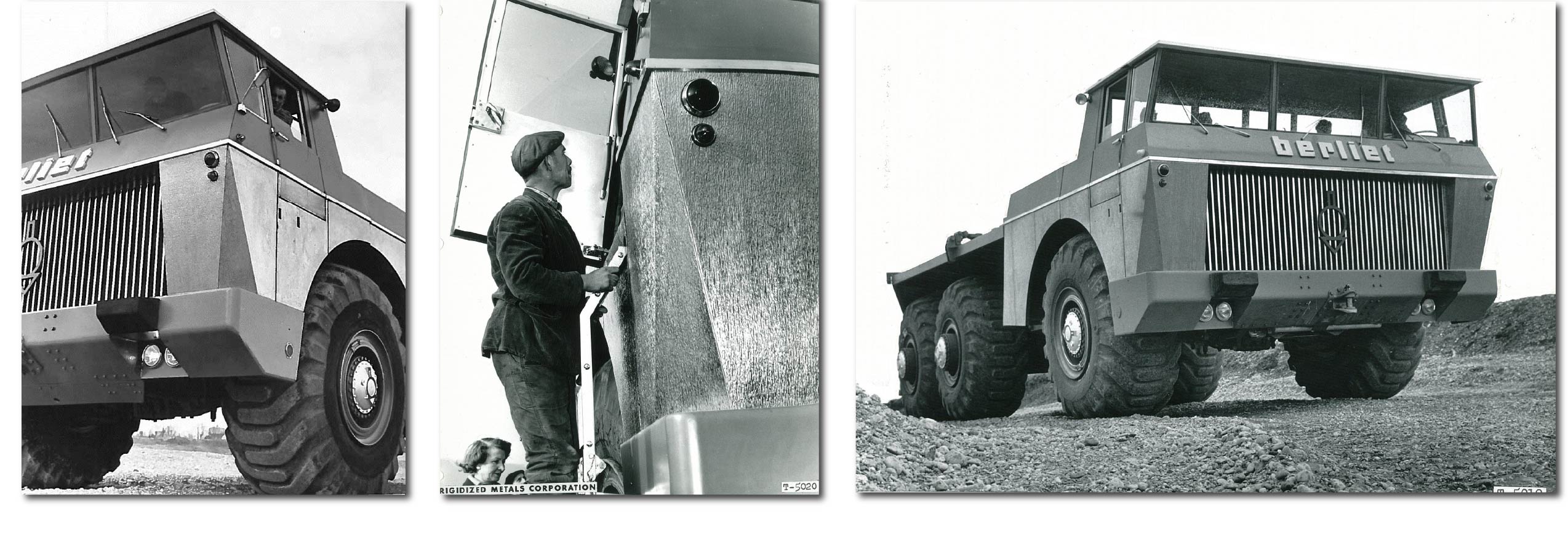

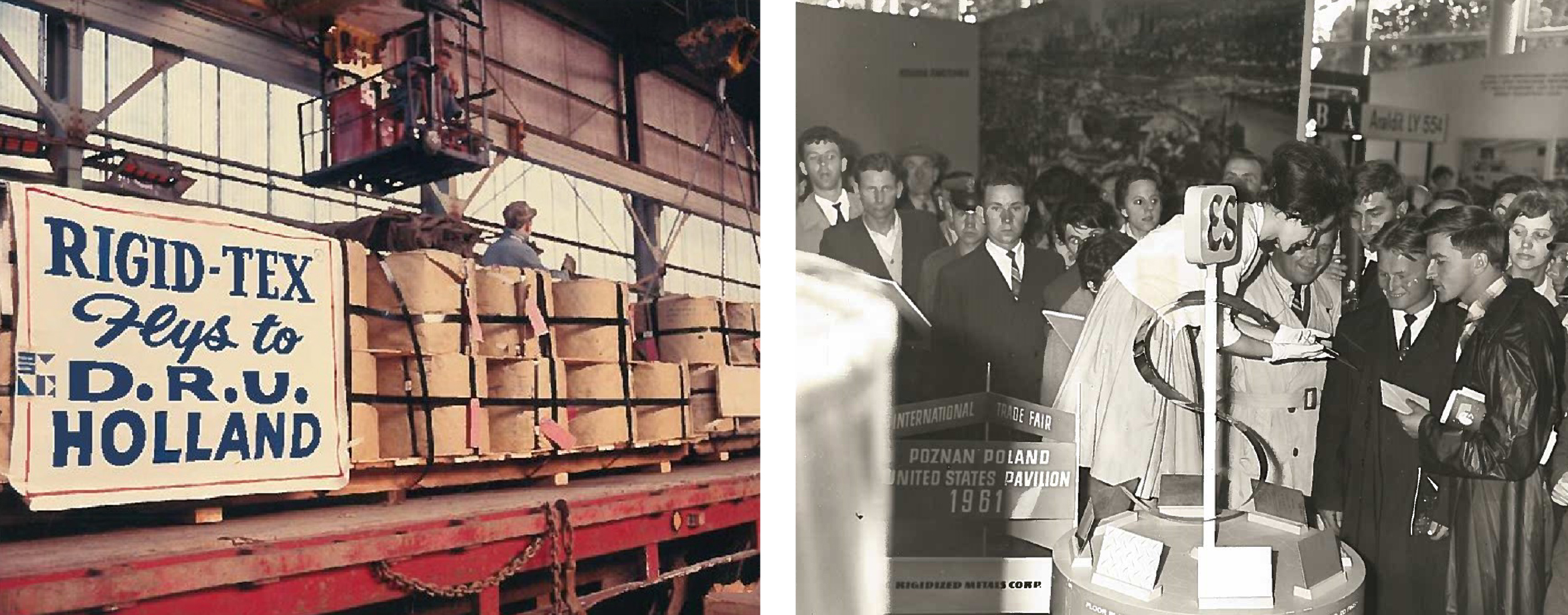

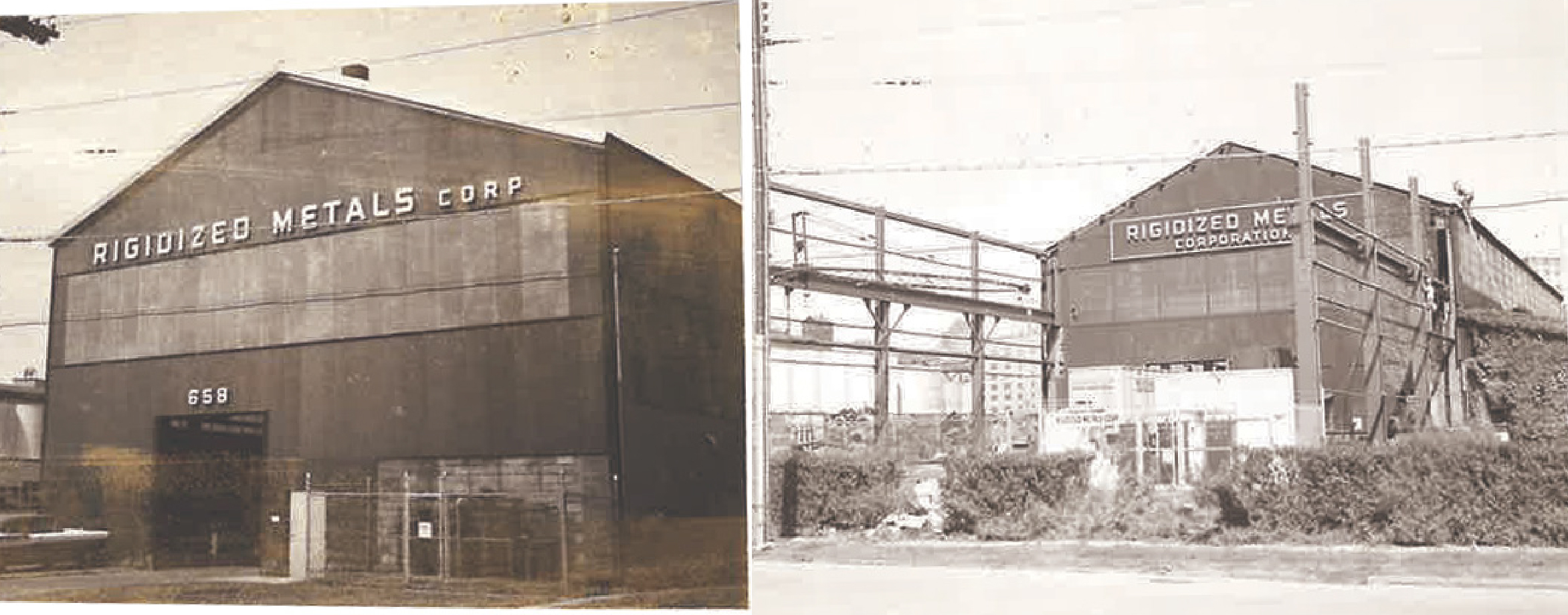

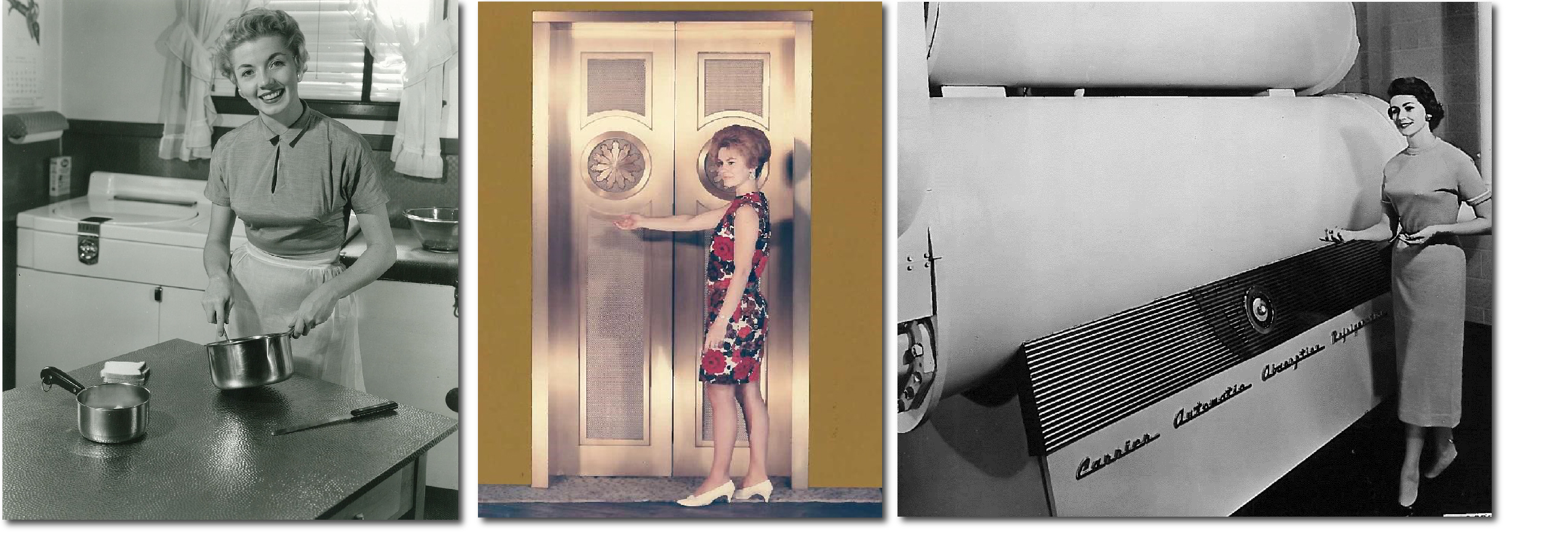

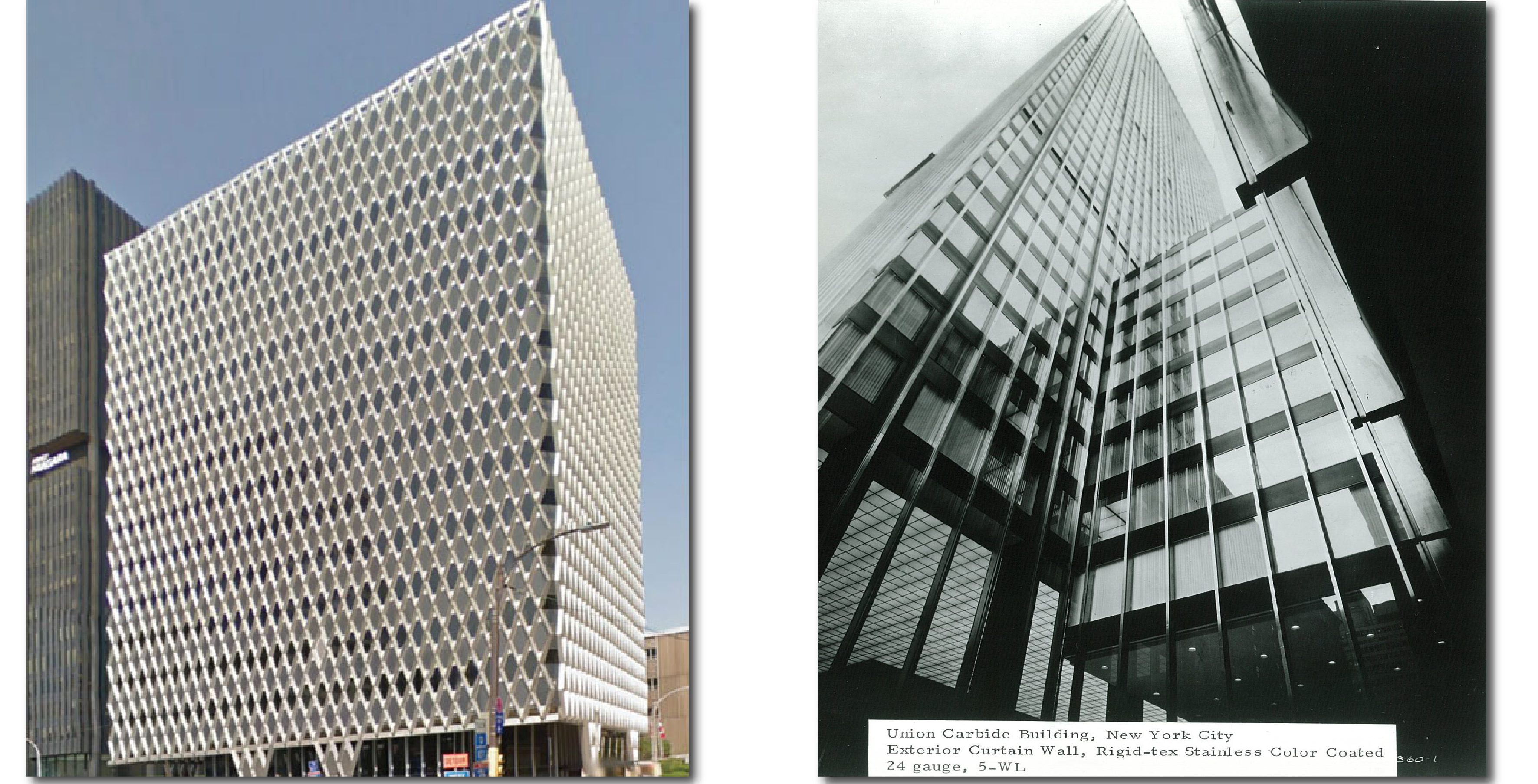

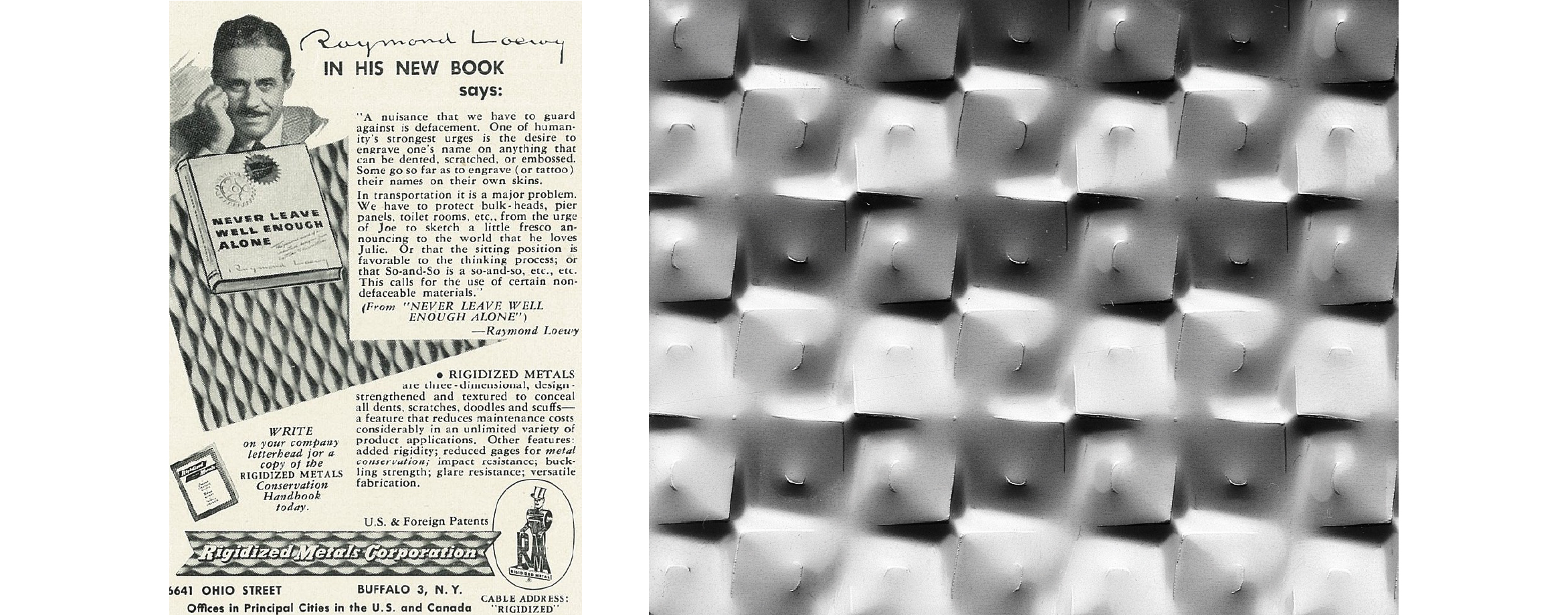

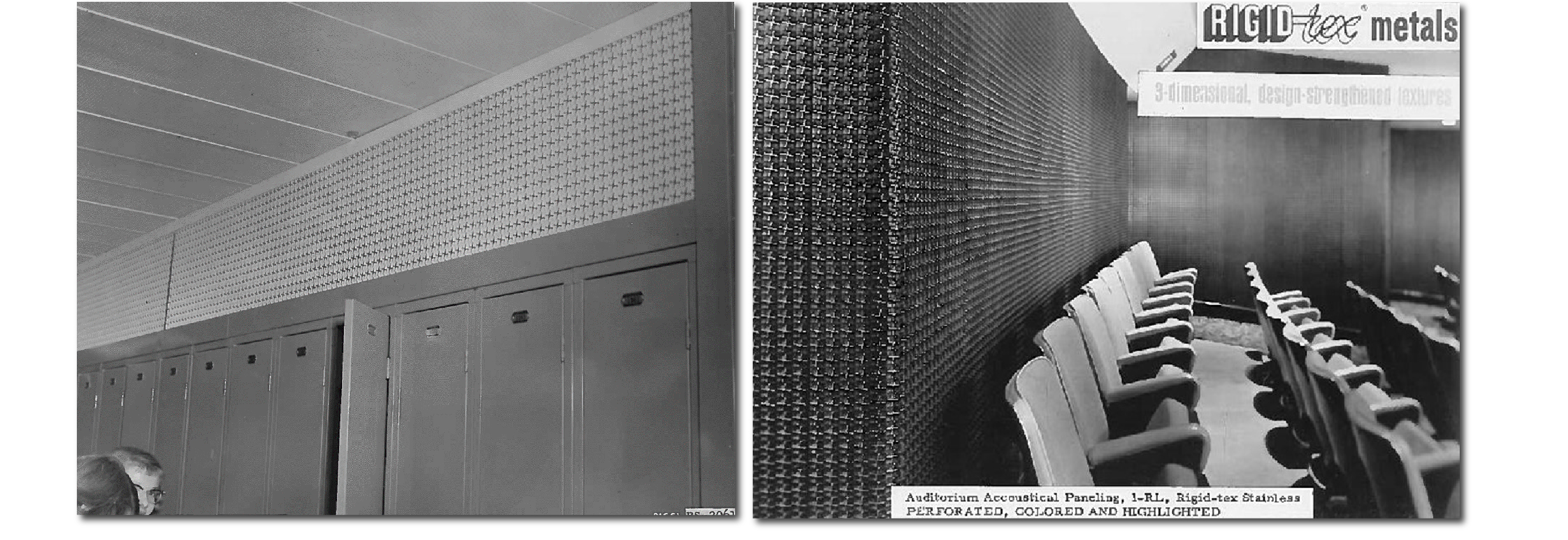

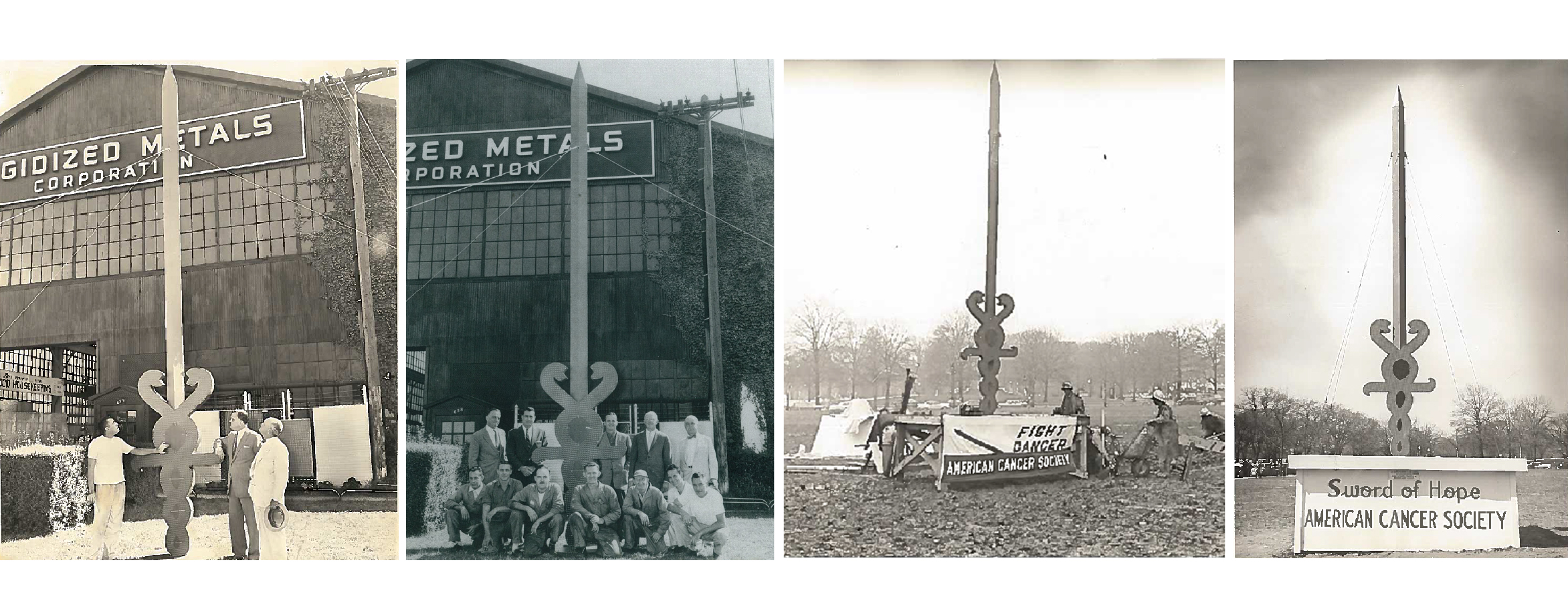

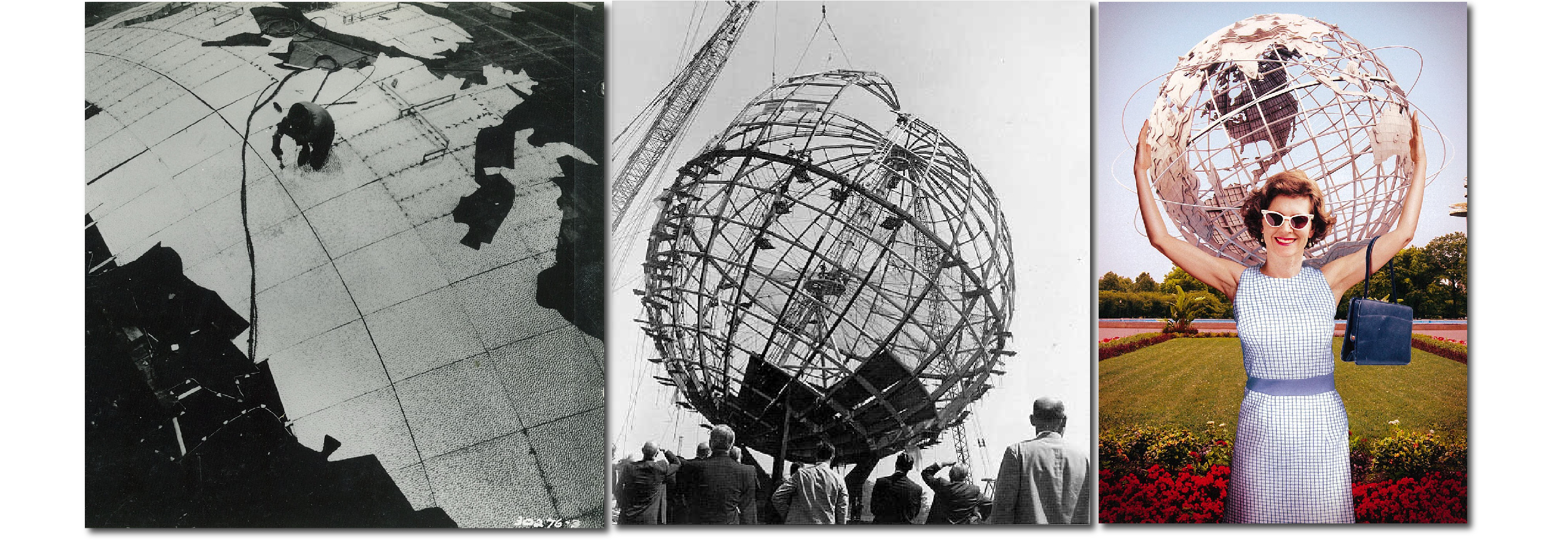

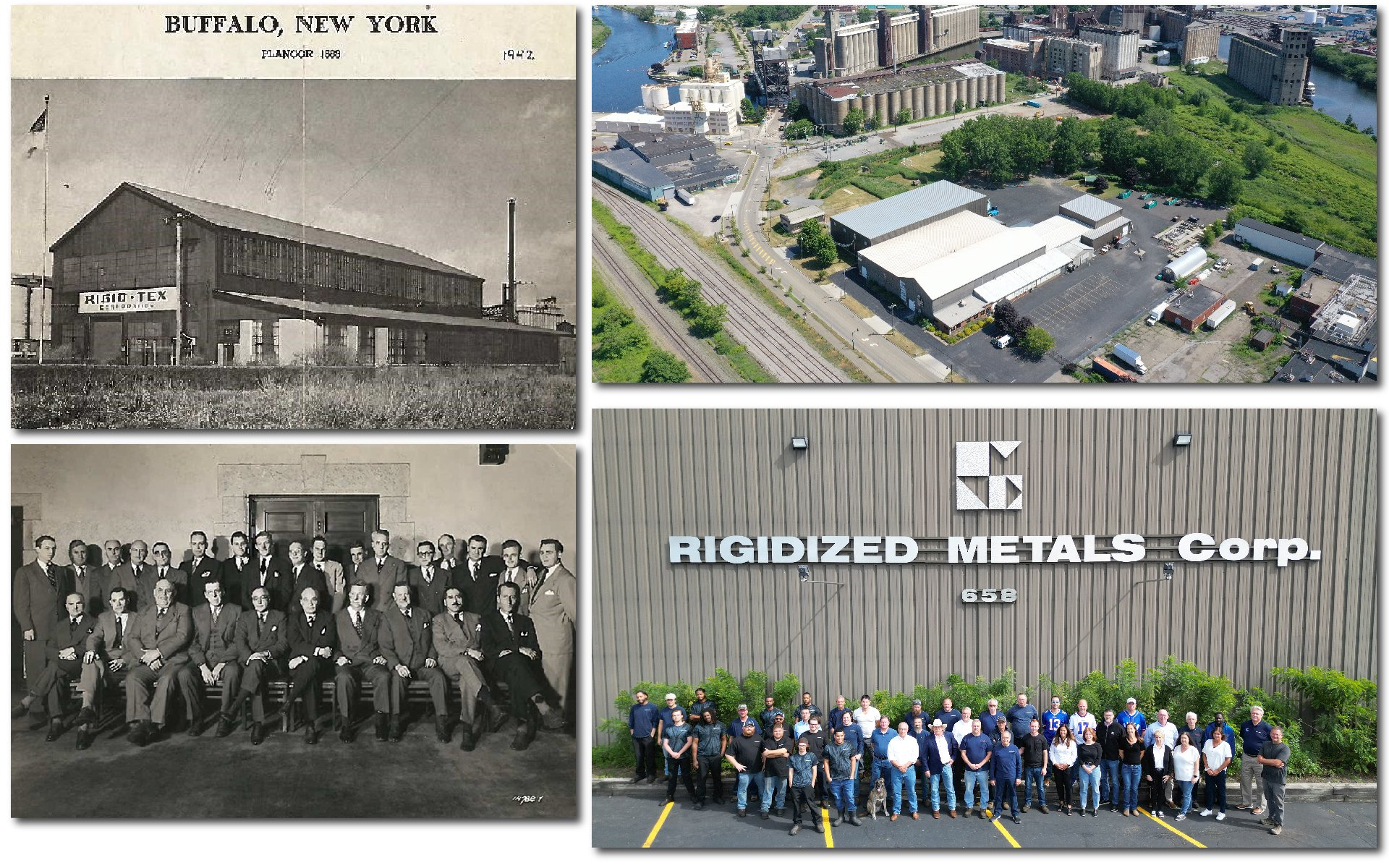

Since 1940, Rigidized Metals Corporation® has led the world in the development and production of deep-textured, three dimensional engineered metal surfaces used in architectural, industrial and transportation applications. Rigidized® Metals products are known for their attractive, economical and functional appeal. The Rigidized® Metals deep-texturing process adds strength, impact resistance and the ability to hide scratches. It also allows for down-gauging, resulting in lighter, longer lasting products and reduced maintenance costs.

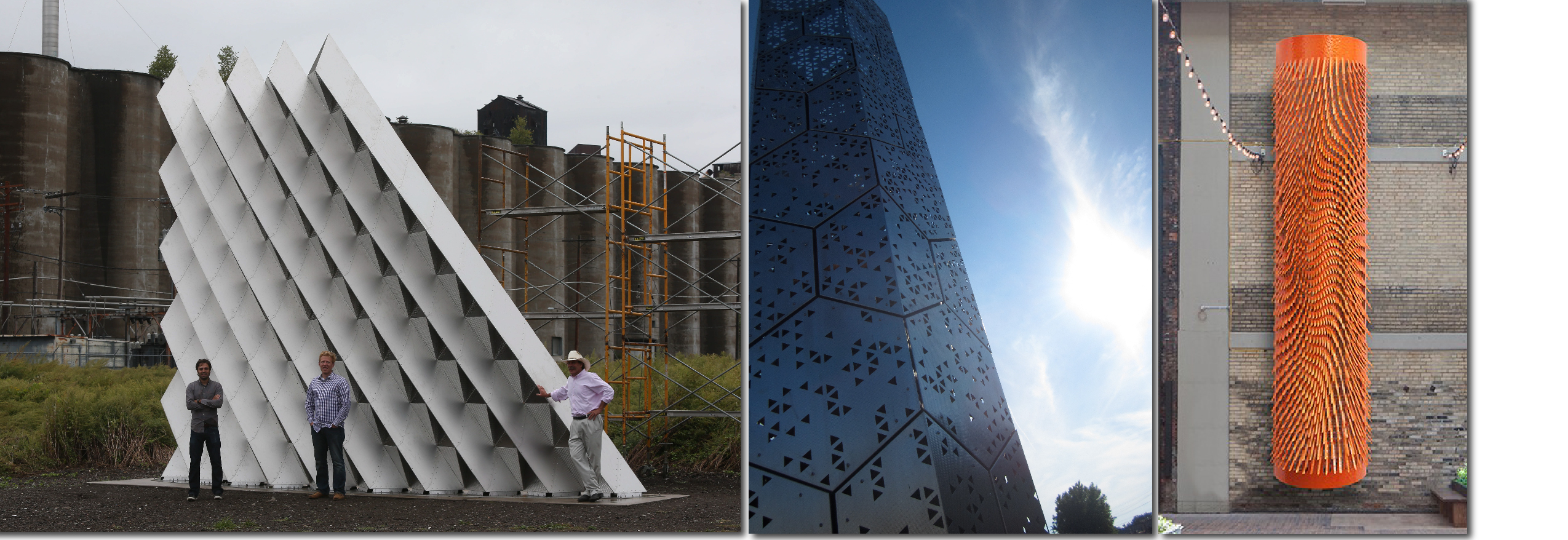

Rigidized® Metals engineered surfaces are available in a wide palette of textures giving the kind of rich surface variation few materials can provide.

We furnish our proprietary Rigidized® Metals engineered surfaces to Service Centers and Original Equipment Manufacturers (OEMs) of countless products around the world. Our patterns include the popular 5WL®, 6WL®, 6SL®, 6HC, 2WL®, RTP® and XTP.