Sustainability

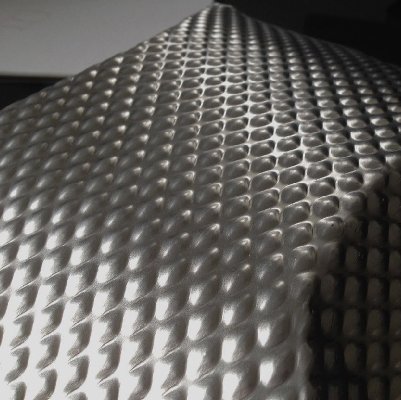

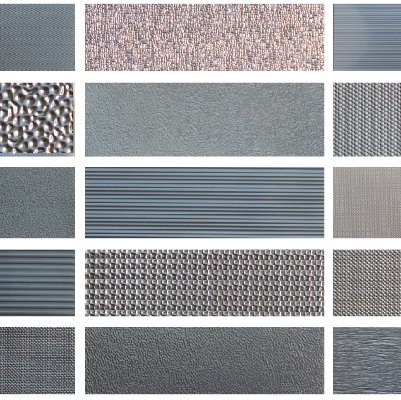

Rigidized® Metals products are a great marriage of beauty and utility. Textured stainless steel is playing an important role in sustainable design and alternative energy evolution. Ultimately, the most environmentally friendly materials are corrosion-resistant and durable, have high recycled content and recapture rates, provide long service life and reduce resource use. Rigidized® Metals engineered surfaces provide all of these benefits. If the correct alloy is selected and properly maintained, it will last the life of the project.

01. Weight and Material Reduction

Rigidized® Metals products are design-strengthened to last. The deep texturing process allows the use of lighter gauges (thickness of metal) because of significantly improved strength-to-weight ratios. For example, down-gauging from 16GA to 18GA results in a material savings of 20%. Using less metal creates less strain on resources and the environment.

02. Durable and Long-Lasting

Engineered surfaces resist dents, hide scratches, and hide fingerprints, making them last longer and look cleaner than ordinary metals. Ultimately, the most environmentally friendly materials are corrosion resistant and durable, and stainless steel facades have been known to provide up to 80 years of service life in architectural projects without appearance deterioration or metal replacement. When properly selected, fabricated, and maintained, it should last the life of the structure. Products made from Rigidized® Metals materials simply look better for longer, require less effort to maintain, and are made from fewer raw materials.

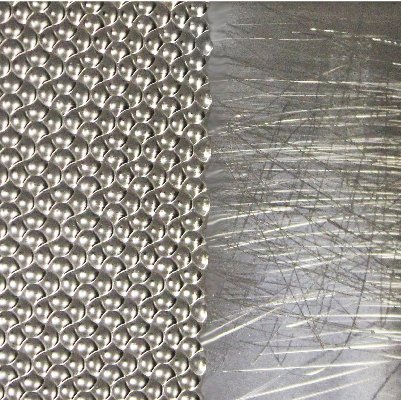

03. Sourced from Recycled Content

A vast majority of the metals Rigidized® Metals transforms are steel and aluminum. Both materials have high levels of recycled content and are 100% recyclable. On average, the recycled content of stainless steel is 60%. Throughout the stainless steel industry, it is widely accepted that any given “heat” of stainless will be composed of the following materials:

- 25% post-consumer waste*

- 35% post-industrial waste*

- 40% raw materials*

In North America and other parts of the world, which have historically used more stainless steel, recycled contents can be higher. The stainless steel producing members of the Specialty Steel Industry of North America have indicated that the average recycled content of the 300 series stainless steel grades that are used in the architectural, building and construction markets is approximately 75-85%*.

*Source: Specialty Steel Industry of North America

04. Recyclable

Steel is North America’s #1 recycled material. Each year, more steel is recycled in the US than paper, plastic, aluminum and glass combined. This is because steel scrap is 100% recyclable, has a high scrap value, an infinite recycling cycle, and is an essential raw material in making new steel. As a result, each year millions of tons of steel are recycled at the end of their service life, diverting material from landfills and recapturing for use in new steel. This use of steel scrap to make new steel conserves energy, reduces emissions and conserves natural resources**.

**Source: Steel Recycling Institute (SRI).

05. Clean Health Rating

Rigidized® Metals products are a sustainable choice for interior building surface applications because they produce no volatile organic compound (VOC) emissions and do not require a surface coating that can deteriorate to possibly pollute the environment. This makes them ideal for buildings where control of the interior air quality is critical and where low air VOC levels are desired. It also offers excellent cleanability; cleaning stainless steel requires no environmentally hazardous or dangerous chemicals. A study by EUROFER concluded that stainless steels themselves do not cause adverse effects on health and so do not need to be classified as hazardous to health.***

***Source: “Manufacture, Processing, and Use of Stainless Steel: A Review of the Health Effects” Published in January 1999 by the EUROFER (European Confederation of Iron and Steel Industries)

Environmental Impact & Responsibility

Our philosophy regarding architectural metals is to select a product that will last the useful life of the building with little or no maintenance. This usually results in the least long-term cost to the building owner. In addition, significantly less harm can be made to the environment by using long life materials as opposed to more commonly used materials that require maintenance and replacement. Learn more, here.

For more information please visit www.usgbc.org.

Explore additional benefits of Rigidized® Metals’ engineered surfaces.